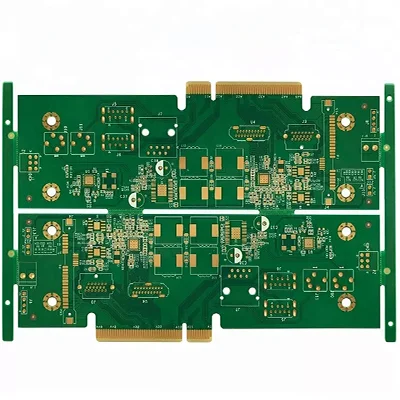

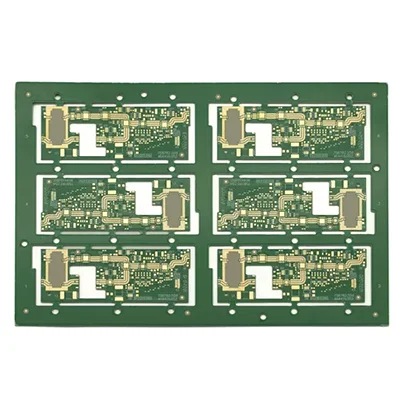

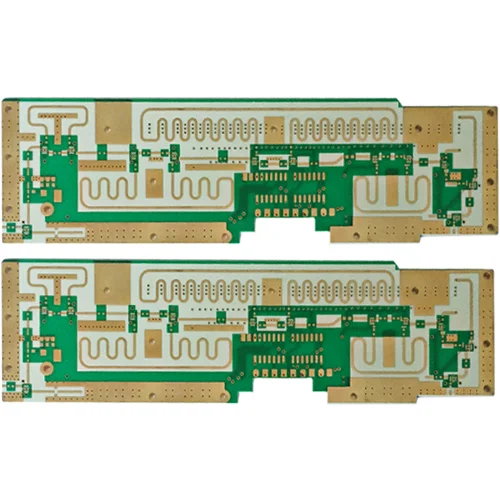

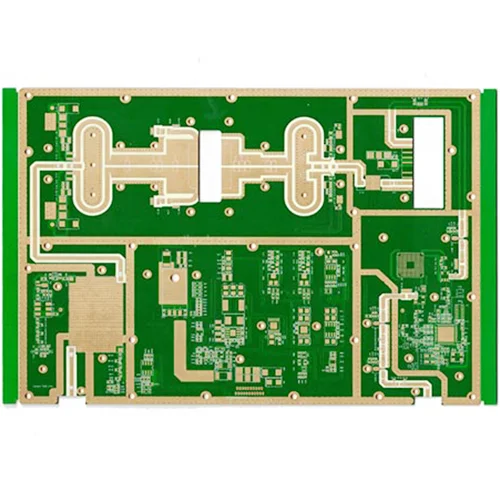

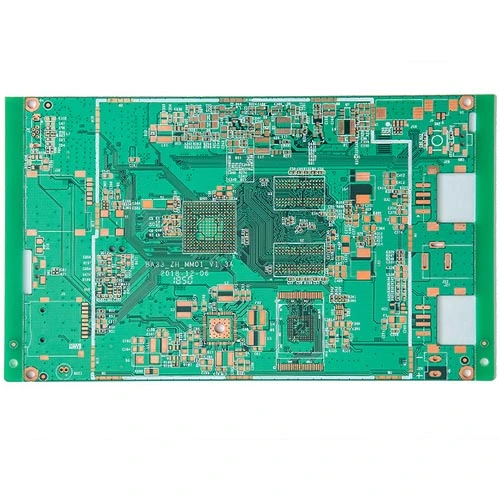

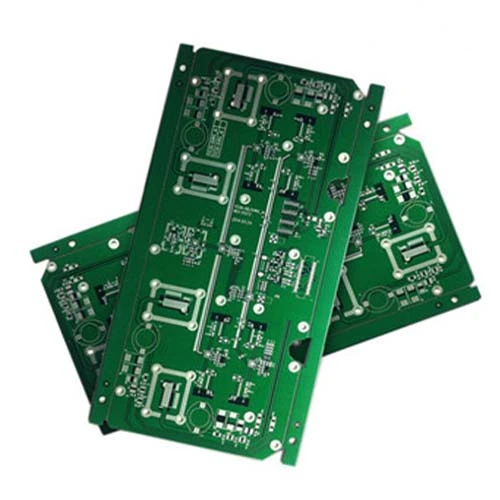

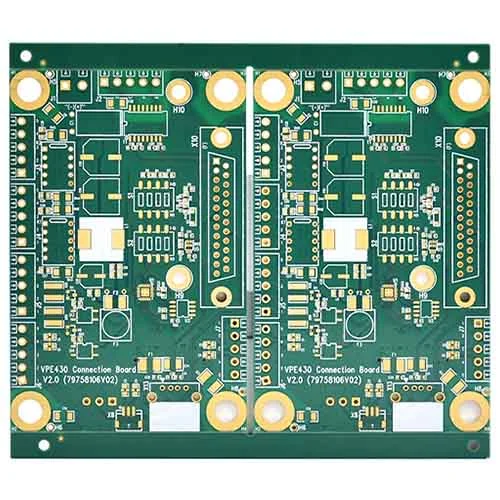

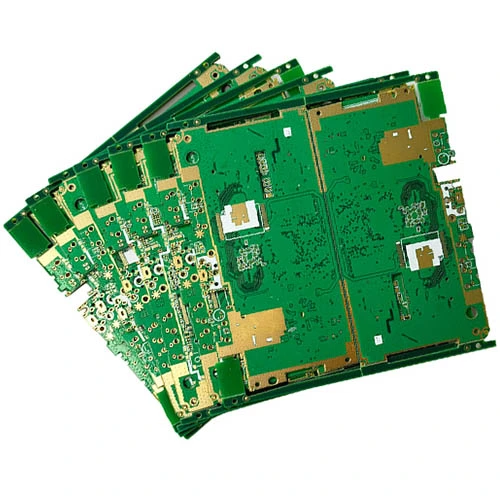

OSP Anti-oxidation PCB Circuit Board

Send Inquiry

Composition of OSP:

General ingredients: alkylbenzimidazole, organic acid, copper chloride and deionized water.

Advantages of OSP

1. Thermal stability. Compared with FLUXK, which is also a surface treatment agent, it was found that after OSP was heated twice at 235℃, there was no entanglement on the surface and the protective film was not damaged. Take two samples of OSFP and ELUX respectively and put them into 6NC, 10% constant temperature submersible at the same time. After one week, there was no obvious change in the OSP sample, while there were small spots on the surface of the FULX sample, that is, it was blocked. Oxidation after heating.

2. Simple management. The OSP process is relatively simple and easy to operate. Customers can use any welding method for processing without special treatment; In circuit production, there is no need to consider the surface uniformity problem. There is no need to worry about the concentration of its liquid, the management method is simple and convenient, and the operation method is simple and easy to understand.

3. Low cost. Since it only reacts with the bare copper part to form a non-stick, thin and uniform protective film, the cost per square meter is lower than other surface treatment agents. Cheap

4. reduce pollution, OSP does not contain harmful substances that directly affect the environment, such as: lead and lead compounds, bromine and bromide, etc. On the automated production line, the working environment is good and the equipment requirements are not high

5. it is convenient for downstream manufacturers to assemble, and the surface treatment of OSP is smooth. When printing tin or pasting SMD components, it reduces the deviation of parts and reduces the probability of empty soldering of SMD solder joints.

6. OSP circuit boards can reduce poor solderability. During the production process, inspectors are required to wear gloves to prevent hand sweat or water droplets from remaining on the solder joints, causing their components to decompose.

In an environment where global customers use lead-free explosion connections, general surface treatment is very suitable. Because the OSP process does not contain harmful substances, the surface is smooth, the performance is stable, and the price is low. Using a simple surface treatment process will be the leader in the circuit board industry. With the trend of surface treatment, high-density BGA and CSP are also beginning to be introduced and used.

Data Sheet

| Product name: | OSP anti-oxidation PCB circuit board |

| PCB material: | FR-4 |

| Copper foil thickness: | 35UM |

| Size: | 68. 36*34. 6mm |

| Minimum aperture: | 0. 45mm |

| PCB thickness: | 1. 6mm |

| Line width and line distance: | 0. 15mm/0. 20mm |

| PCB process: | OSP anti-oxidation |