Quality Assurance

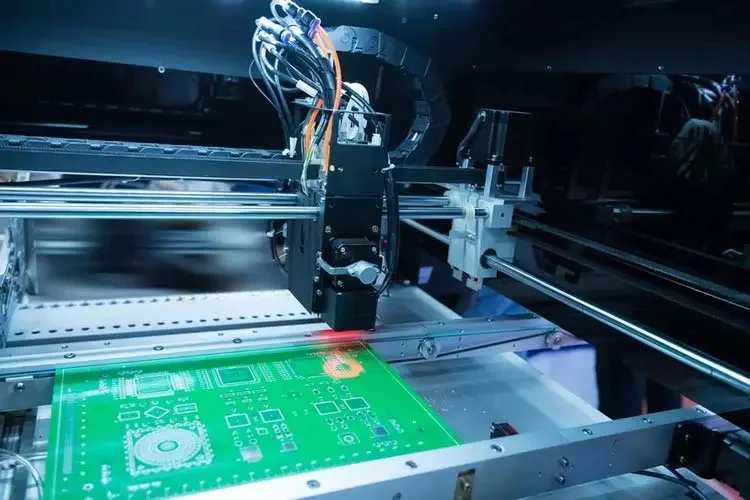

When manufacturing and assembling printed circuit boards, the quality of the finished product will be one of your main concerns.

In order to achieve the highest level of manufacturing quality, it is most important to find an excellent manufacturer like Guang dong Viafine PCB LIMITED that follows the control methods for manufacturing and assembling PCB quality.

Guang dong Viafine PCB LIMITED provides printed circuit boards, components and electronic systems.

We will provide safe, effective and reliable products while providing higher quality and value to our customers.

Guang dong Viafine PCB LIMITED has always been eager to achieve excellence in different stages of manufacturing and product control and has been recognized by important international certification bodies recognized by the global electronics industry.

Incoming material quality control

Incoming inspection refers to the quality confirmation and inspection of purchased raw materials, components or products, that is, when the supplier sends out the raw materials or components, the quality of the raw materials or components is sampled and inspected, and finally it is judged whether the batch of products is accepted.

Choosing a trustworthy platform is another important way to get quality components. These companies accurately meet the requirements of customers.

In addition, they provide high-quality parts after passing the testing pipeline.

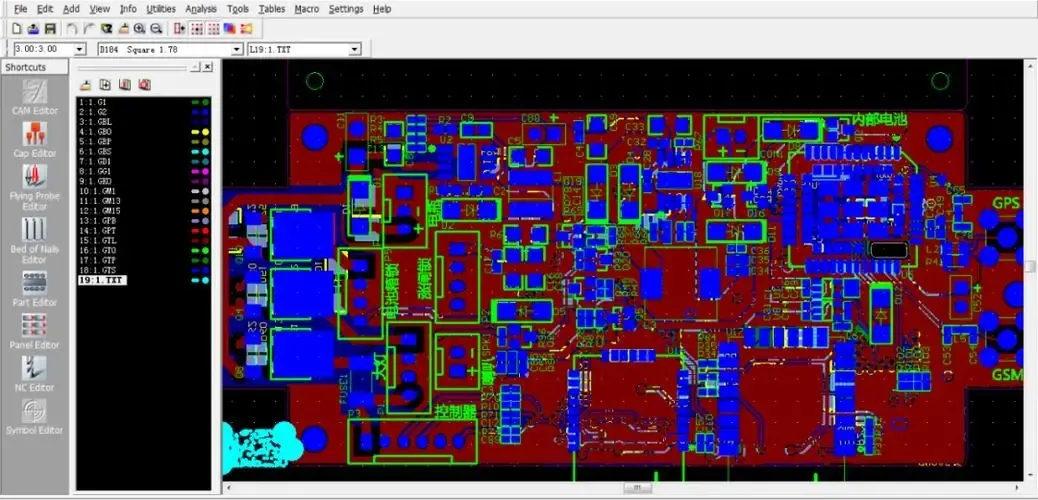

Free DFM Check

At Guang dong Viafine PCB LIMITED, we provide customers with free DMF checks, which usually include signal and mixed layer checks, power/ground checks, drilling checks, solder mask checks, and silk screen checks to ensure that every detail is correct. Our engineers will immediately send engineering inquiries to our customers when they find any information that does not match the original file.

First Article Inspection

The first article inspection system is a quality management system that integrates inspection equipment and data platform.

You only need to enter the BOM table of the product, and the inspection unit in the system will automatically inspect the first sample and check the data in the BOM table.

The automated working method of this system can reduce human errors, improve efficiency, and save labor costs, but the asset and technology investment is large.

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) testing is very common in the SMT industry and is applicable to all circuit board production and PCB assembly.

It is mainly used to judge the welding problems of components by the appearance characteristics of components.

It is also possible to judge whether there are wrong components on the circuit board by checking the color of the components and the silk screen on the IC.

Basically, each SMT production line will be equipped with one or two AOI devices as standard.

Automatic X-ray Inspection

For some circuit boards with BGA packaged components, the first product produced needs to be X-ray inspected.

X-rays have strong penetrability and are the earliest instruments used in various inspection occasions.

The perspective view can show the thickness, shape, quality and density of solder joints.

These specific indicators can fully reflect the welding quality of solder joints, including open circuits, short circuits, hole copper, internal bubbles, insufficient tin, etc., and can be quantitatively analyzed.

Automatic fixture tester

Automatic fixture testing is usually used for mass production of PCBs.

Its characteristics are that the production volume is usually large and the test efficiency is high, but the manufacturing cost is high.

Each circuit board requires a special fixture, and the life of each set of fixtures is not very long, generally one year.

In order to meet customer quality and delivery requirements, Guang dong Viafine PCB LIMITED purchased multiple automatic test fixtures to reduce labor costs.

Burn-In Test

The main purpose of aging test is to simulate the daily use environment of the product through the combined effects of high temperature, low temperature, high and low temperature changes, and electric power, and expose the defects of PCBA, such as poor welding, mismatch of component parameters, and debugging process.

Aging test can eliminate and improve the defects of PCBA, and will play a role in stabilizing the parameters for defect-free PCBA boards.

Fly Probe Test

Flying probe test is usually used for some small batch production.

Its characteristics are convenient testing, strong program variability, and good versatility.

Basically, all types of circuit boards can be tested. However, the test efficiency is relatively low, and it takes a lot of time to test each board.

This test needs to be performed after the product passes through the reflow oven.

It mainly measures the resistance value between two fixed points to determine whether the components in the circuit board have short circuits, empty solder joints, and wrong parts.

In-Circuit Test

Online testing is usually used on models that have been mass-produced. The production volume is usually large, the test efficiency is high, but the manufacturing cost is relatively high.

Each type of circuit board requires a special fixture, and the test cost is very high.

The test principle is similar to the flying probe test. It also measures the resistance between two fixed points to determine whether the components on the circuit have short circuits, empty soldering and wrong parts.

Function Test

This test method is usually used on some more complex circuit boards.

The circuit board to be tested must be soldered and passed through some specific fixtures to simulate the official use of the circuit board.

Put the circuit board in this simulation. On site, after turning on the power, observe whether the circuit board can be used normally.

This test method can accurately judge whether the circuit board is normal. But there are also problems of low test efficiency and high test cost.

PCB quality assurance:

Meet customers' PCB manufacturing and PCB assembly with the highest quality.

Guang dong Viafine PCB LIMITED has implemented the ISO9001 quality system.

A complete quality assurance system and various testing equipment help us monitor the entire production process, ensure the stability of the process and the quality of the product, and introduce advanced instruments and technologies to achieve continuous improvement.

Quality policy

Quality first, customer first, continuous improvement, excellence

Environmental policy

◾ Strictly abide by the laws and regulations on pollution prevention and control.

◾ Continuously improve processes to save resources.

◾ Gradually manufacture environmentally friendly products for the benefit of human society

Health and Safety Policy

◾ Strictly comply with laws and regulations regarding employee health and safety.

◾ Continuously create a healthy and safe working environment.

◾ Comprehensively prevent potential risks that endanger health and safety.

Quality

◾ 100% visual inspection and electrical testing

◾ Test data

◾ Industrial computer

◾ Certification- ISO 9001

◾ XRF test data

◾ Solderability test

◾ Impedance modeling/testing

PCB assembly quality assurance:

To comprehensively strengthen quality control, we must achieve our quality policy and goals.

The quality system is established in accordance with ISO9001:2015, and internal audits are conducted regularly to ensure the effective operation of the quality system.

All employees participate in the quality system and continuously train and learn. Customer satisfaction is our mission.

IQC: Incoming material inspection

◾ First piece inspection for each process

◾ IPQC: In-process quality control

◾ AOI inspection

◾ In-circuit test (ICT)

◾ Functional test (FCT)

◾ Reliability test