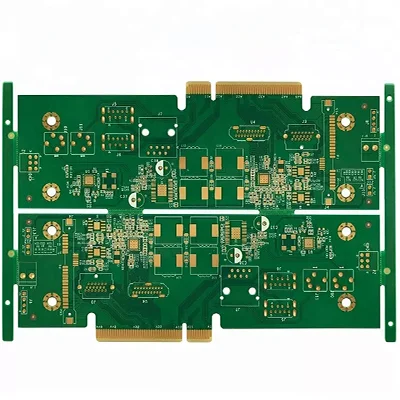

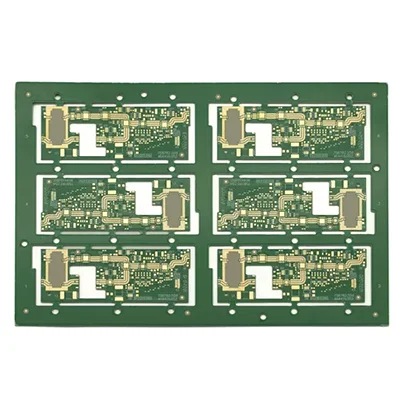

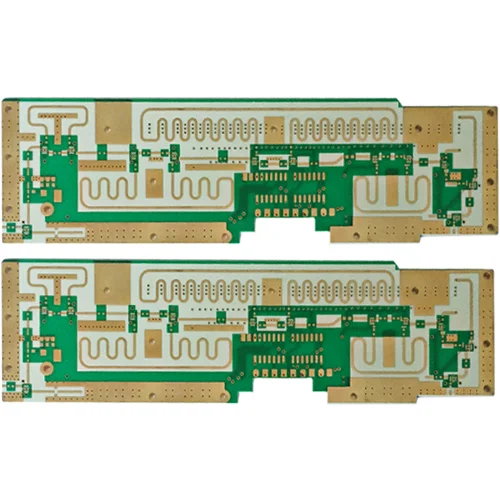

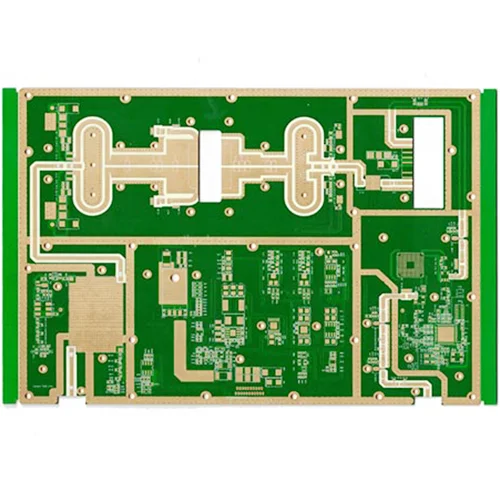

Gold Finger Printed Circuit Board

Send Inquiry

PCB gold finger details processing

As a professional Gold Finger Printed Circuit Board manufacturer, you can rest assured to buy Gold Finger Printed Circuit Board from our factory and Viafull will offer you the best after-sale service and timely delivery. 1. In order to increase the wear resistance of gold fingers, gold fingers usually need to be electroplated with hard gold (gold compound).

2. Gold fingers need to be chamfered backwards, generally 45°, other angles such as 20°, 30°, etc. If there is no chamfer in the design, there is a problem; 45° slot in PCB

3. Gold fingers need to make a window for overall welding. PIN does not need to open steel mesh;

4. The minimum distance between Shenxi and Shenyin pads and fingertips needs to be 14mil; It is recommended to design more than 1mm away from the finger position, including via pads;

5. Do not apply copper on the surface of gold fingers;

6. Copper cutting is required at all levels of the inner layer of gold fingers, and the copper cutting width is generally 3mm; Half-finger copper cutting and full-finger copper cutting can be performed.

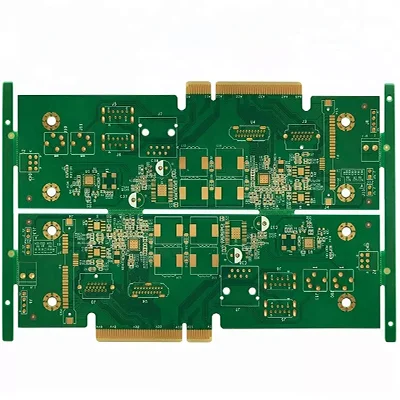

Data Sheet

| Name: | Gold Finger PCB |

| Base material: | FR-4/High TG |

| Copper thickness: | 1 ounce |

| Board thickness: | 1. 6mm |

| Aperture: | 0. 2mm |

| Line width: | 0. 1mm/4mil |

| Line spacing: | 0. 1mm/4mil |

| Surface treatment: | Immersion gold |

| Impedance control: | 50/90/100±10% ohm |

| TG value: | T170 |

| Material flame retardant: | 94v0 |