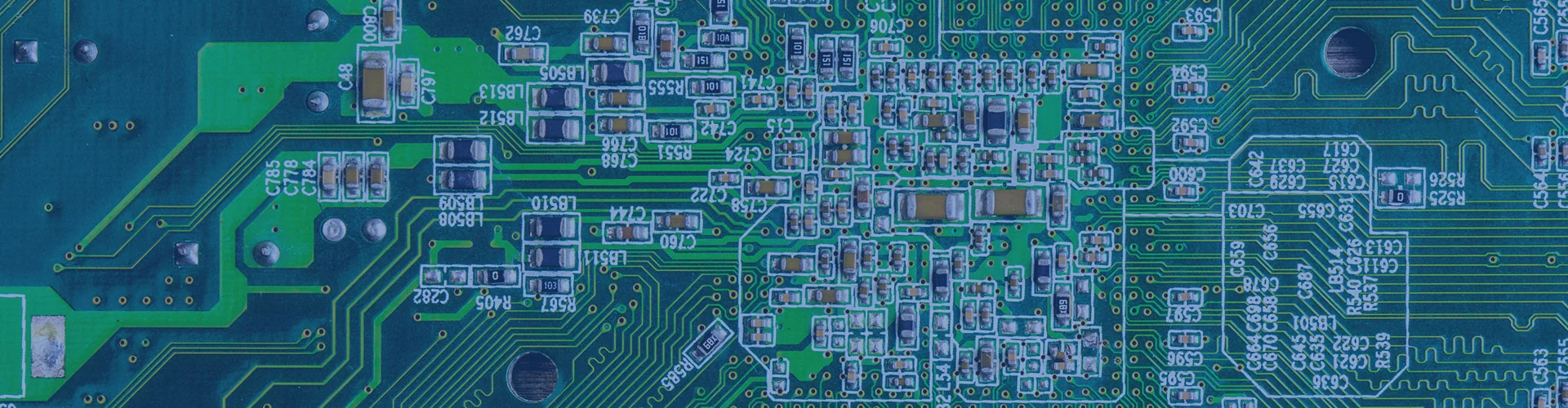

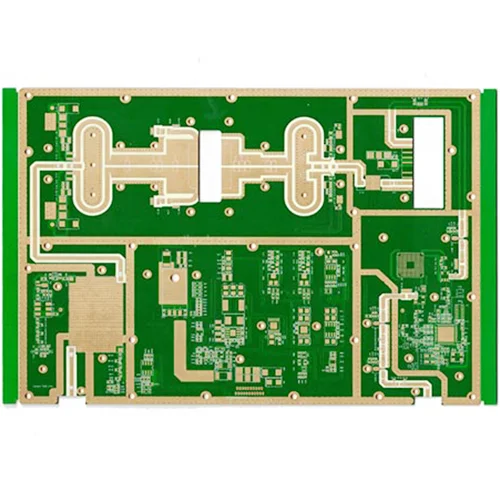

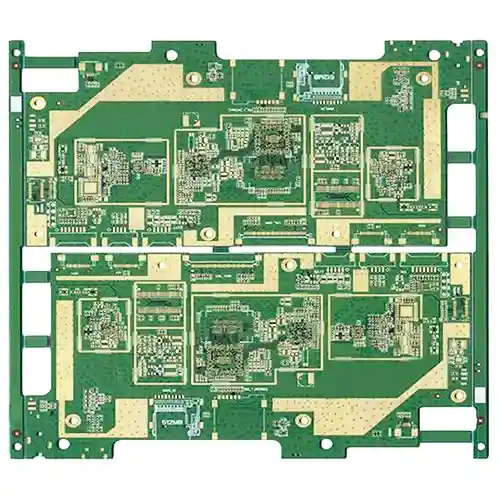

6-layer Industrial Control PCB Motherboard

Send Inquiry

What is a 6-layer board?

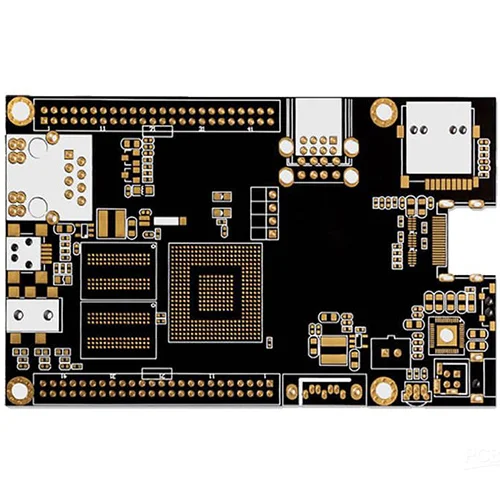

Viafull is one of the famous China 6-layer Industrial Control PCB Motherboard manufacturer and supplier. Our factory specializes in manufacturing of 6-layer Industrial Control PCB Motherboard. A 6-layer PCB is a multi-layer printed circuit board that contains six sheets of conductive material. It is actually mainly a four-layer PCB with two additional signal layers placed between the surfaces.

A standard six-layer PCB consists of the following six layers:

Two outer layers

Two inner planes

Two inner layers

In addition to providing excellent routing for both high-speed and low-speed data, the architecture of a six-layer PCB also reduces electromagnetic interference (EMI). To route high-speed communications, two inner planes must be used in conjunction with two surface layers.

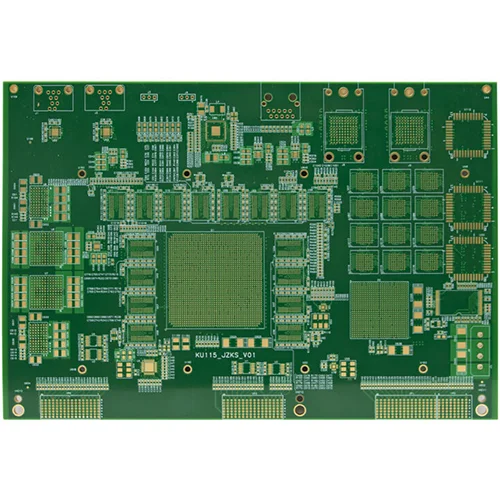

What are 6-layer PCB applications?

According to industry experts, 6-layer PCBs are considered ideal for a variety of industrial applications due to their light weight and compact design. 6-layer PCB applications are as follows:

Industrial electronics

Consumer electronics and industrial electronics are completely different. They can withstand harsh environments such as heat, pressure, vibration, stress, grit, and moisture. They are designed to operate for long periods of time and work continuously. This situation applies to 6-layer PCBs. Today, 6-layer PCBs are more durable than other market alternatives.

Medical Devices

In the medical field, electronics are indispensable. Like all other industries that rely on electronics, the medical industry is miniaturizing.

As non-invasive treatment methods gain momentum, there is an increasing demand for miniature devices in the medical field. 6-layer PCBs are perfect for these devices due to their small size, light weight, and other powerful features. MRI, X-ray, CT scans, blood pressure, IR temperature monitoring are some examples of medical devices that use 6-layer PCBs.

Computers and Devices

We can no longer imagine life without computers. Almost all computers and related devices use 6-layer PCBs due to their excellent space-saving and processing characteristics. The development of these PCBs may outperform other technologies while saving money.

Consumer Electronics

Consumer electronics include a wide range of common electronic devices. Communication devices such as smartphones and laptops, entertainment devices such as smart TVs and media players, and home appliances such as microwave ovens and washing machines are examples of such products. Most of these gadgets have 6-layer PCBs compared to traditional single-layer PCBs. Why? 6-layer PCBs help them to be simplified and small in size.

Military, Aerospace, and Defense

Like the above industries, the military and defense sector is giving priority to 6-layer boards. This type of PCB is popular for its small size, light weight, practicality, and durability.

Surveillance, aircraft defense systems, radar systems, and automated weapons use 6-layer printed circuit boards. Advanced circuits require 6-layer PCBs to withstand harsh environments where high temperatures and high pressures can damage advanced components.

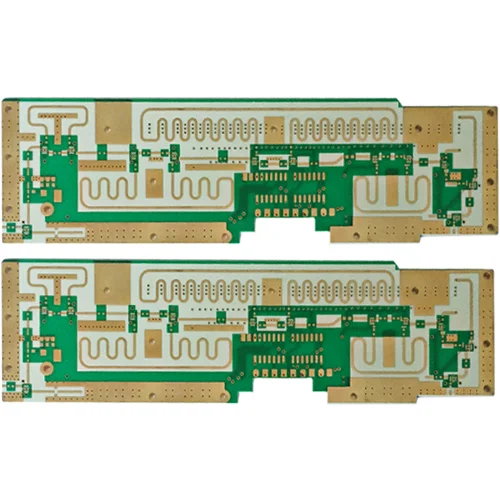

Telecommunications Electronics

Many communication devices, such as GPS and satellite systems, use 6-layer PCBs for communication systems, which require durability and functionality. With the development of wireless communications, there is an increasing demand for high-performance small devices. 6-layer circuit boards meet the demand with ease.

Other telecommunications electronics applications include power amplifiers, telecommunications towers, radar systems, and more.

What are the advantages of 6-layer PCBs?

In terms of technology, 6-layer PCBs have many design advantages. If you use 6-layer PCBs, you will get the following advantages:

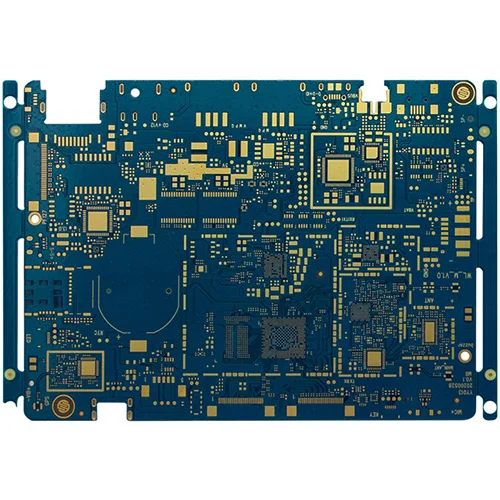

Small Size

One of the main and recognized advantages of using 6-layer PCBs is their size. Due to their layered architecture, they are naturally smaller than other PCBs of comparable performance.

This provides a significant advantage for modern electronics as the current trend is towards smaller, more compact yet more powerful devices such as smartphones, computers, tablets, and smartwatches.

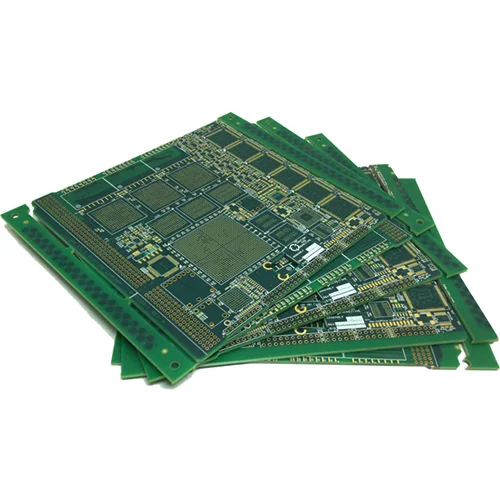

High Quality

Due to the amount of work and preparation required to build a 6-layer PCB, these types of PCBs are more efficient in quality than single and double-layer boards. As a result, they tend to be more stable.

Increased Durability

By their nature, 6-layer PCBs can be strong. These 6-layer printed circuit boards are not only able to support their loads, but also withstand the pressure and temperature required to bond them securely.

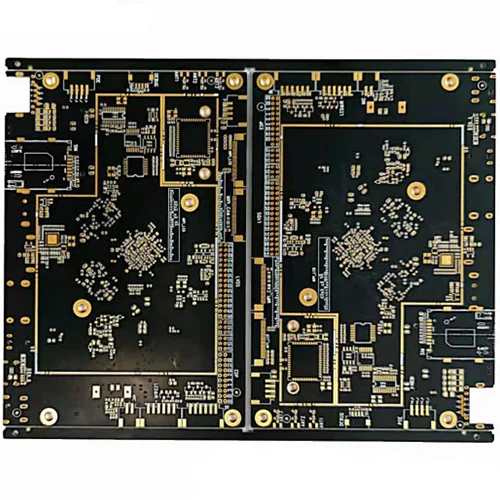

More Robust

They are densely packed into multiple layers on a single PCB. These narrow end plates make their connections tighter and help them achieve higher speeds and reliability at a smaller size.

Single Connection Point

They are designed to operate independently of other PCB components. As a result, they only require a single connection point, rather than the multiple connection points required for several single-layer PCBs.

This also benefits electronics designers as only a single connection point is required for the finished product. This is perfect for small devices and gadgets. However, these characteristics make 6 layer PCBs ideal for mobile devices and high-performance electronics. With so many industries now adopting mobile solutions, 6 layer PCBs are finding new possibilities.

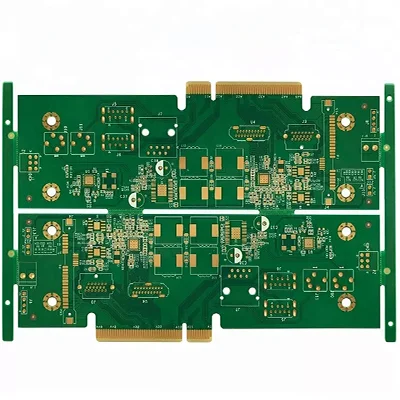

Data Sheet

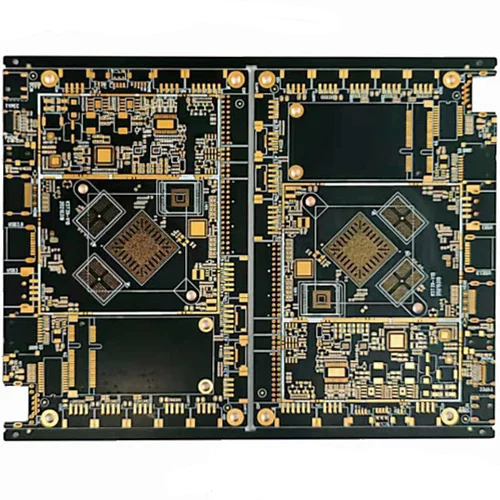

| Name: | 6-layer industrial control PCB motherboard |

| Number of layers: | 6L |

| Sheet: | FR4 TG150 |

| Board thickness: | 1. 6mm |

| Panel size: | 190*150mm/2 |

| Outer copper thickness: | 35μm |

| Inner copper thickness: | 35μm |

| Minimum through hole: | 0. 20mm |

| Minimum BGA: | 0. 35mm |

| Line width and spacing: | 3/3mil |

| Surface treatment: | immersion gold 2U'' |