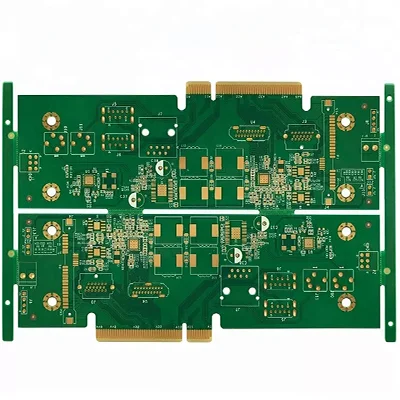

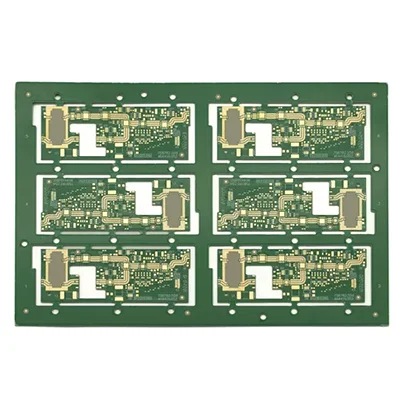

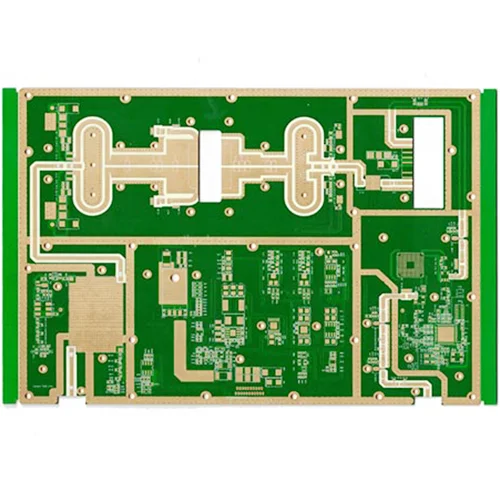

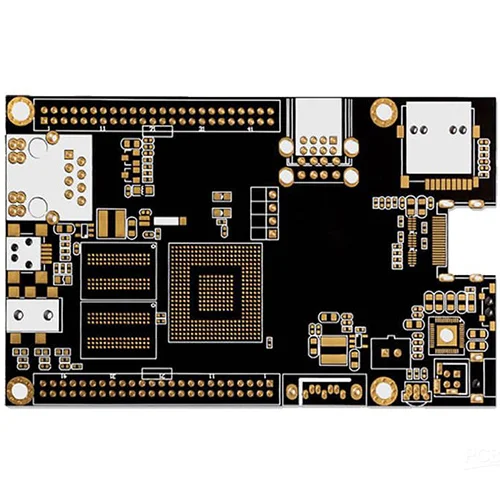

12-layer PCB Circuit Board

Send Inquiry

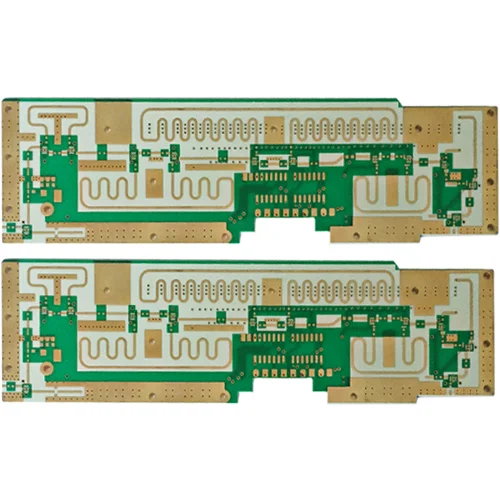

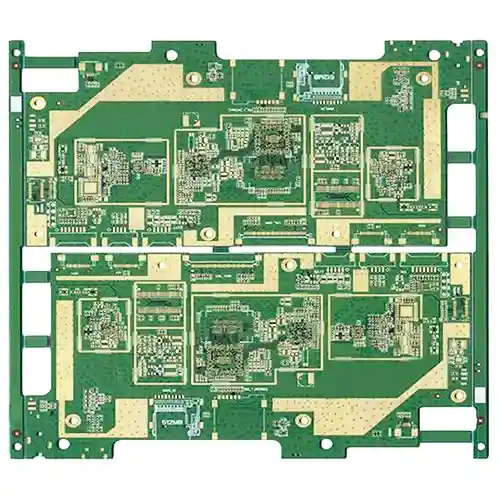

12-layer PCBs lay the foundation for modern automotive electronic circuits. They play an important role in fast-tracking reliable interconnections. This type of PCB has a variety of uses, including navigation systems, transmission control units, electronic ignition assembly systems, and other components of vehicles.

12-layer PCBs are designed to withstand stress conditions and high temperatures. The main material used here is polyimide. This polyimide material is organic in nature and has good heat resistance.

Some top PCB manufacturers use gold when finishing 12-layer PCBs. This is because it plays a huge role in withstanding harsh environments. In addition, some applications that add heat sinks to ensure that the PCB operates at high temperatures are easily dissolved.

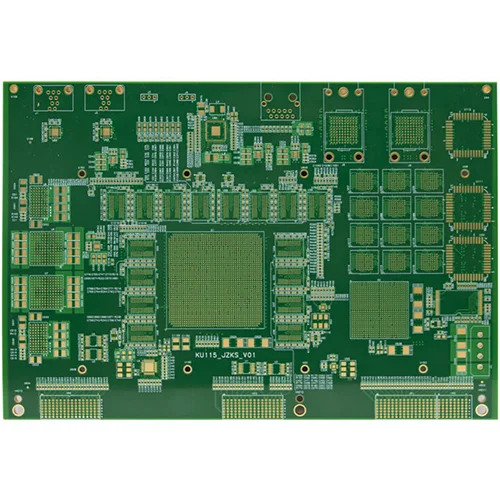

In addition, at a temperature of 288 degrees Celsius and 20 seconds, 12-layer PCBs withstand thermal stress while its impedance is controlled at around +/-10%. The cost of purchasing 12-layer PCBs is affordable compared to other multi-layer boards such as 8-layer and 10-layer.

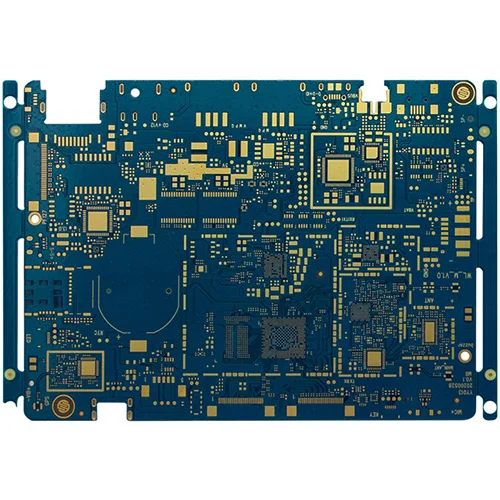

12-layer printed circuit boards can be used in the following areas:

Consumer electronics

Computer electronics

Telecommunications

Medical equipment

Aerospace and military

Data Sheet

| Name: | 12-layer PCB circuit board |

| Number of layers: | 12L |

| Sheet: | FR4 TG150 |

| Board thickness: | 1. 2mm |

| Panel size: | 114*96mm/2 |

| Outer layer copper thickness: | 35μm |

| Inner layer copper thickness: | 35μm |

| Minimum through hole: | 0. 20mm |

| Minimum BGA: | 0. 35mm |

| Line width and line spacing: | 3. 8/3. 8mil |

| Surface treatment: | immersion gold 2U'' |