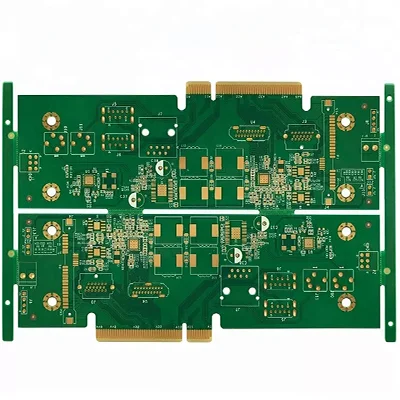

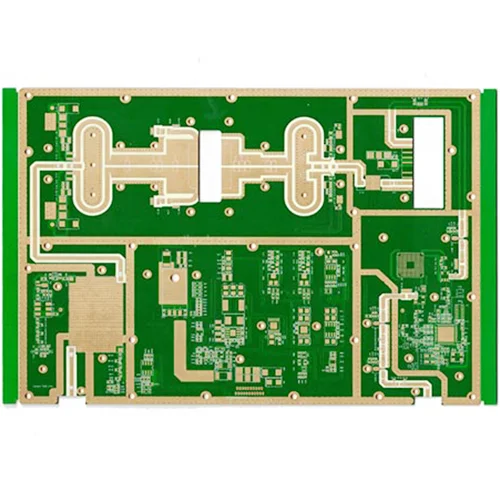

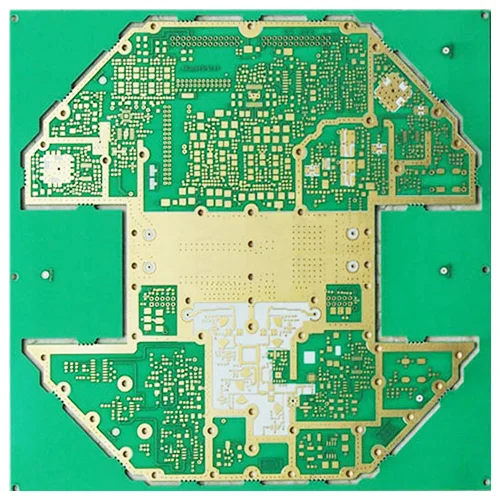

T2.0 Rogers 4003 PCB

Send Inquiry

RO4003C™ Laminates

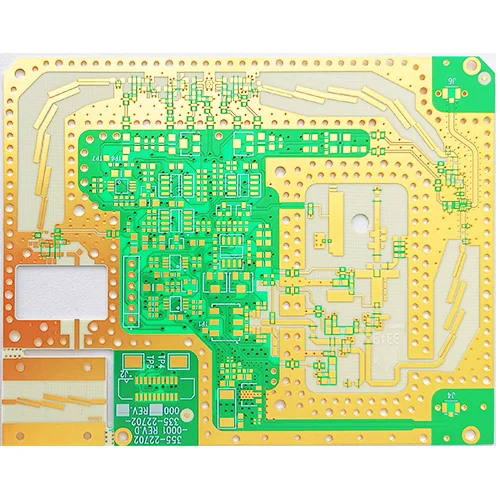

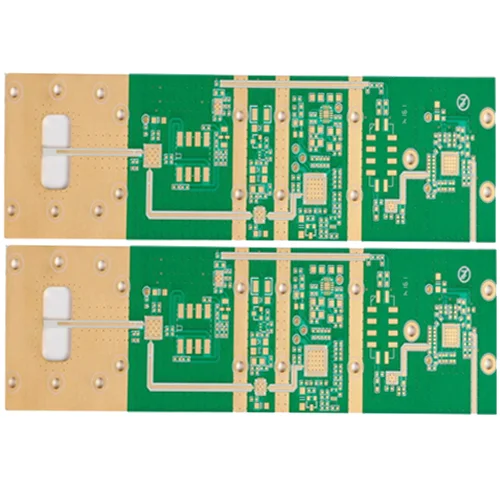

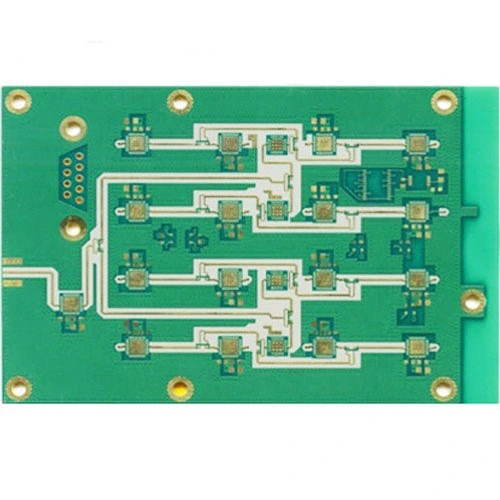

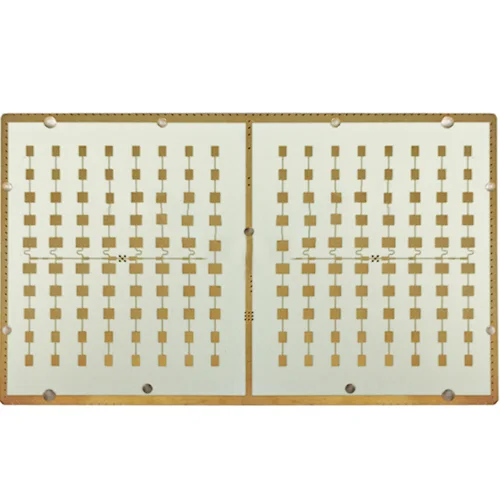

Viafull invites you to visit our factory to purchase the newest, best-selling, affordable, and high-quality T2.0 Rogers 4003 PCB. We are looking forward to working with you. Rogers RO4003C material is a proprietary woven glass reinforced hydrocarbon/ceramic that has the electrical properties of PTFE/woven glass and the manufacturability of epoxy/glass.

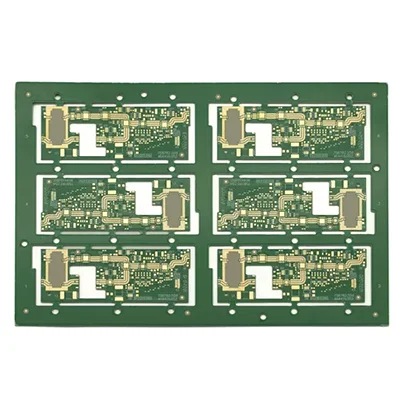

RO4003C laminates are available in multiple configurations with 1080 and 1674 fiberglass styles, all meeting the same laminate electrical performance specifications. RO4003C laminates offer tightly controlled dielectric constant (Dk) and low loss while using the same processing methods as standard epoxy/glass, but at a fraction of the cost of traditional microwave laminates. Unlike PTFE-based microwave materials, no special through-hole treatments or handling procedures are required.

RO4003C material does not contain bromine and does not meet the UL 94 V-0 rating. For applications or designs that require a UL 94 V-0 flammability rating, RO4835™ and RO4350B™ laminates do meet this requirement.

Features

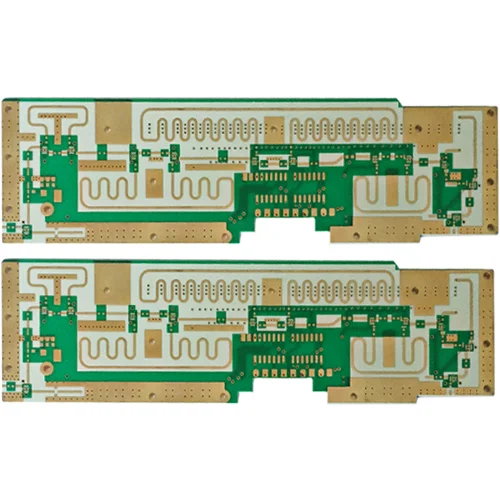

Dk of 3. 38 +/- 0. 05

Dissipation factor of 0. 0027 at 10 GHz

Low Z-axis thermal expansion at 46 ppm/°C

Benefits

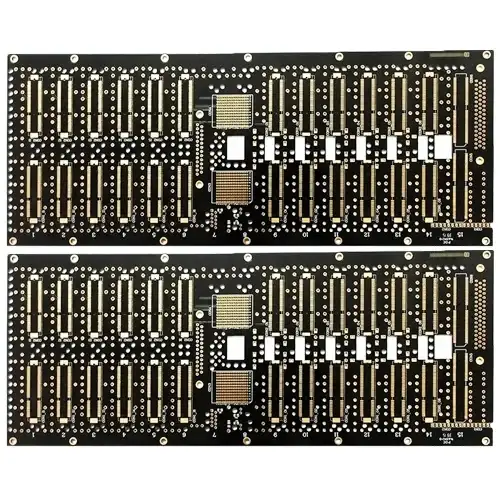

Ideal for multi-layer board (MLB) construction

Lower manufacturing cost in processes such as FR-4

Designed for high-volume, performance-sensitive applications

Competitively priced

Data Sheet

| Name: | Rogers 4003 PCB |

| Rogers 4003 dielectric constant: | 3. 38 |

| Number of layers: | 4003+4450F |

| Rogers 4003 thickness: | 0. 508mm (20mil) |

| Finished product thickness: | 2. 0mm |

| Rogers 4003 substrate copper thickness: | 17μm |

| Finished product copper thickness: | 1OZ |

| Surface treatment: | immersion gold |

| Color: | green/white |

| Minimum trace/space: | 6 million/6 million |

| Features: | Rogers PCB, tg280 high temperature resistant PCB |