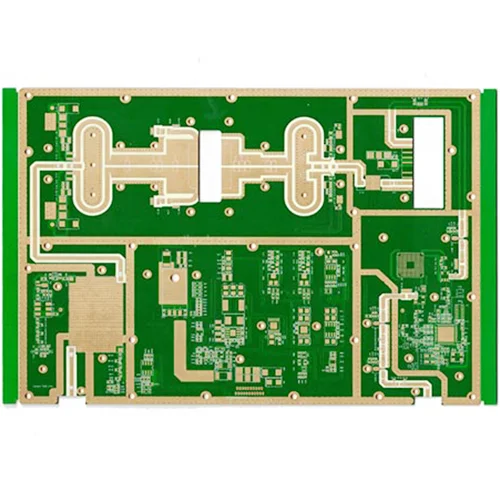

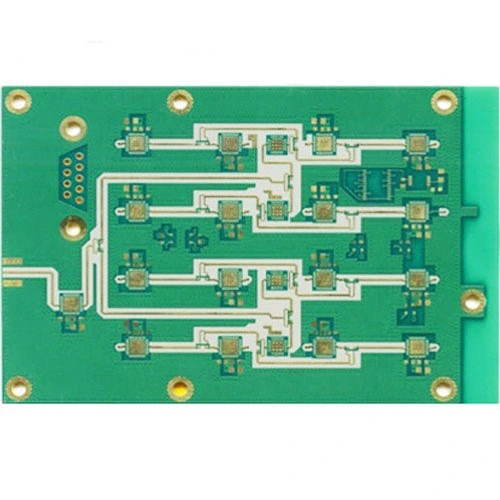

Rogers RT5870 High Frequency Board

Send Inquiry

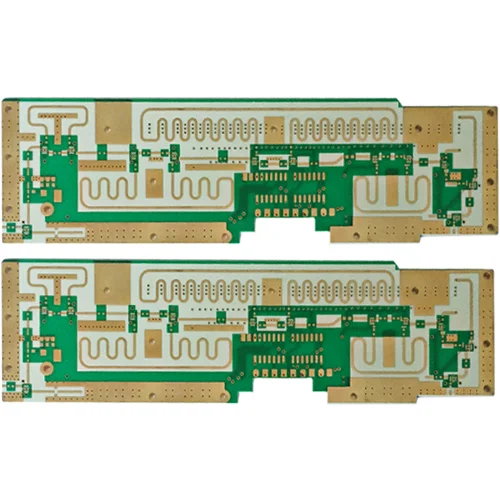

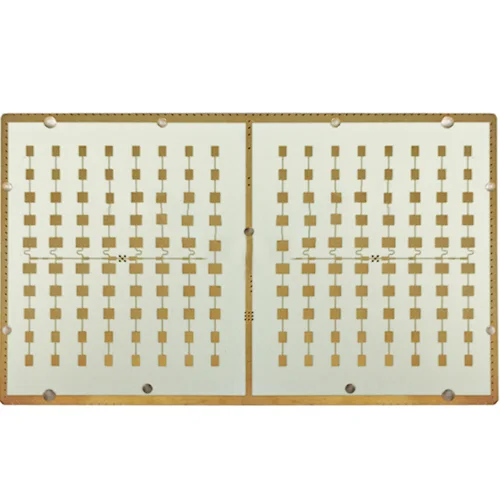

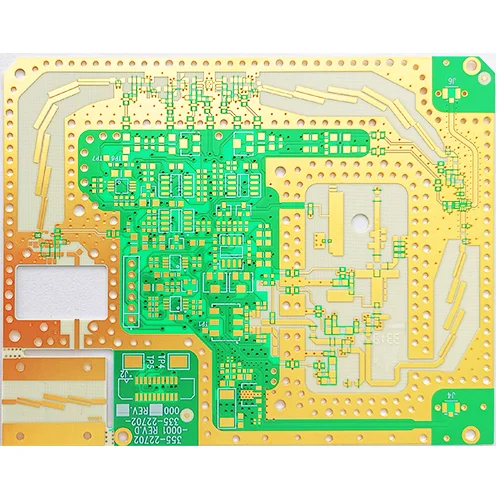

RT/duroid® 5870 and 5880 glass microfiber reinforced PTFE composites are designed for precision stripline and microstrip circuit applications.

The glass reinforcement microfibers are randomly oriented to maximize the benefits of fiber reinforcement in the orientation that is most valuable to the circuit manufacturer and the final circuit application.

The dielectric constant of RT/duroid 5870 and 5880 laminates is consistent from panel to panel and constant over a wide frequency range. Their low dissipation factor extends the use of RT/duroid 5870 and 5880 to Ku-band and above.

RT/duroid 5870 and 5880 laminates are easily cut, sheared, and machined to shape. They are resistant to all solvents and reagents, both hot and cold, and are typically used to etch printed circuits or plate edges and holes.

RT/duroid 5870 and 5880 composites are typically supplied as laminates with ¼ to 2 oz/ft2 (8 to 70 microns) of electroplated copper on both sides and can also be clad with rolled copper foil for more critical electrical applications. Cladding with aluminum, copper or brass sheeting can also be specified.

When ordering RT/duroid 5870 and 5880 laminates, be sure to specify dielectric thickness, tolerance, rolled or electrodeposited copper foil, and the weight of copper foil desired.

Data Sheet

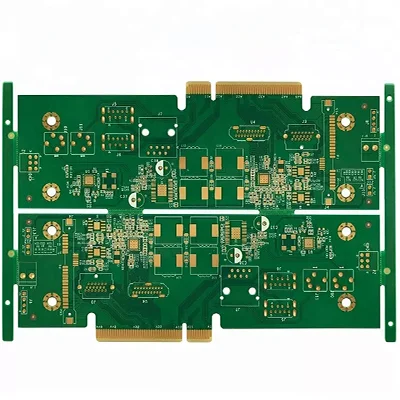

| Product name: | Rogers RT5870 high frequency board |

| Product model: | Rogers RT/duroid 5870 high frequency board |

| Material: | Rogers RT/duroid 5870 |

| Number of layers/board thickness: | 2 layers/0. 9mm |

| Line width/line spacing: | 0. 762mm |

| Application areas: | Commercial aerospace broadband antennas, microstrip lines and strip circuits, millimeter wave equipment, radar systems, missile guidance systems, point-to-point digital RF antennas |