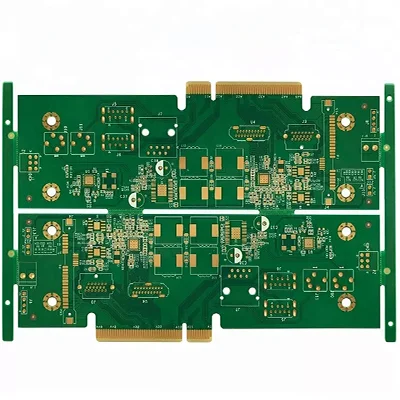

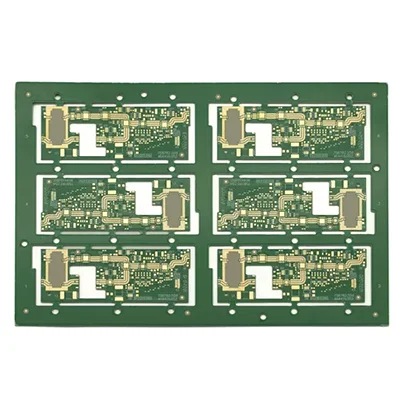

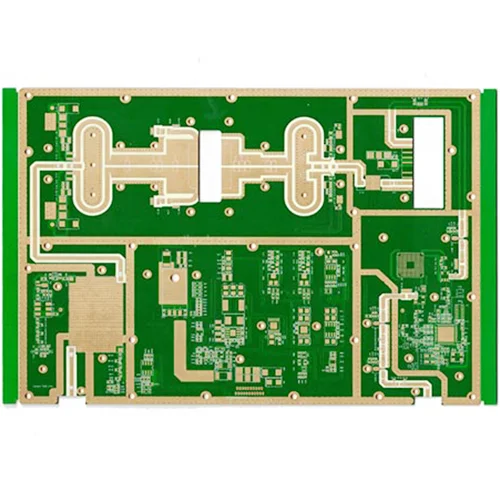

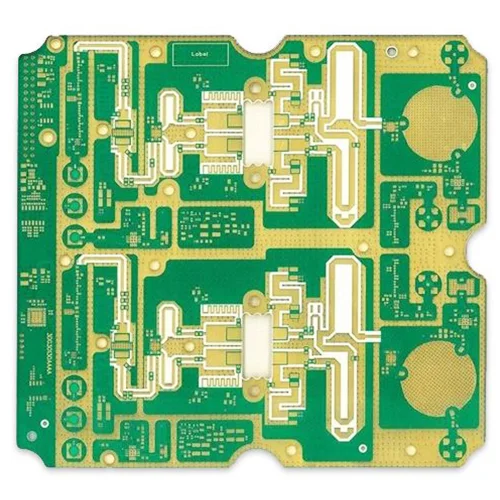

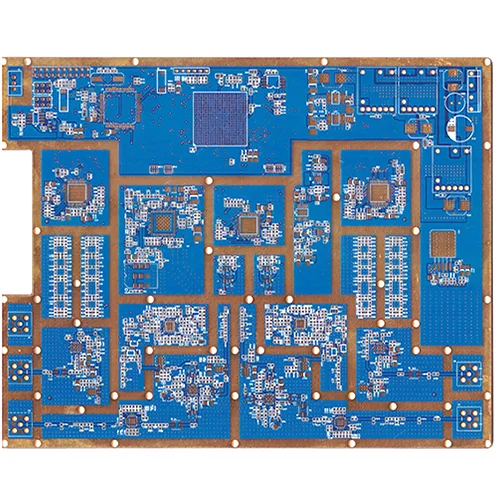

Ro4835 FR4 High Frequency Hybrid Board

Send Inquiry

Ro4835 FR4 High Frequency Hybrid Board is a hydrocarbon ceramic laminate, an oxidation resistant high frequency material for applications requiring higher stability at high temperatures. It is more resistant to oxidation than other hydrocarbon materials. RO4835 laminates are designed to provide excellent high frequency performance and low cost circuit manufacturing. In addition, the electrical and mechanical properties of RO4835 material are nearly identical to RO4350B laminates that customers have successfully used for many years.

Oxidation affects all thermoset laminates over time and temperature. In the long term, oxidation causes a slight increase in the dielectric constant and dissipation factor of the circuit substrate.

Features and Benefits:

1. Significantly improved oxidation resistance compared to typical thermoset microwave materials designed for performance sensitive, high volume applications.

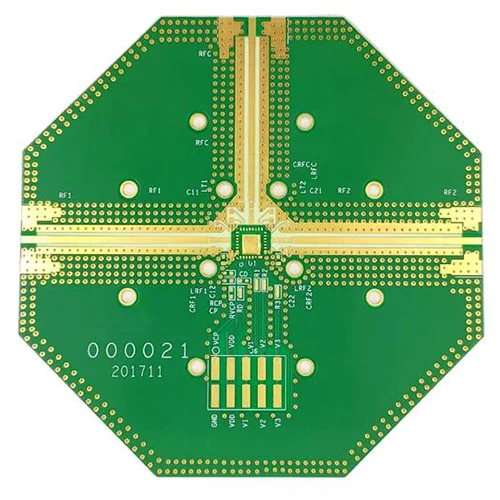

2. Low losses exhibit excellent electrical performance, allowing applications with higher operating frequencies, especially automotive applications.

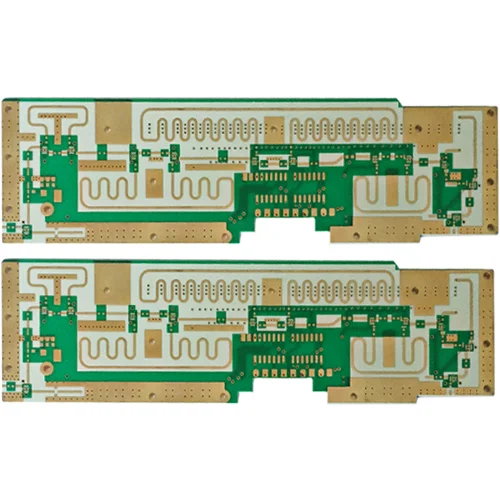

3. Tight dielectric constant tolerance results in controlled impedance transmission lines

4. Lead-free process compatibility without blistering or delamination

5. Low Z-axis spread results in reliable plated through holes

6. Low in-plane expansion coefficient, stable over the entire circuit processing temperature range

Data Sheet

| Product name: | Ro4835+FR4 high frequency hybrid board |

| Board: | Rogers Ro4835+IT180 |

| Number of layers: | 6 layers |

| Board thickness: | 1. 5MM |

| Copper thickness: | finished copper thickness 1OZ |

| Impedance: | 50 ohms |

| Dielectric thickness: | 0. 127mm |

| Dielectric constant: | 3. 48 |

| Thermal conductivity: | 0. 69w/m. k |

| Flame retardant grade: | 94V-0 |

| Volume resistivity: | 1. 2*1010 |