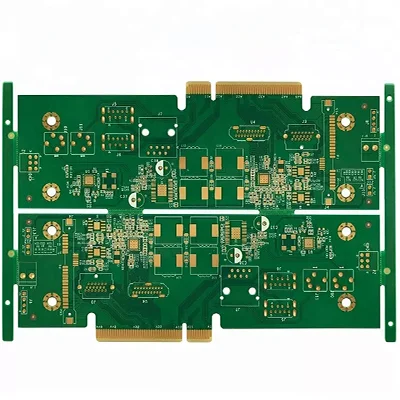

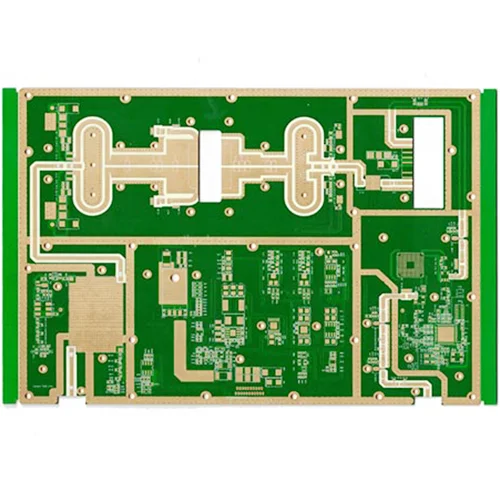

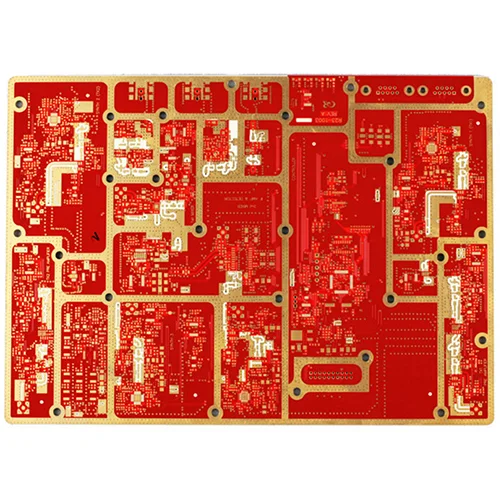

High Frequency Hybrid PCB

Send Inquiry

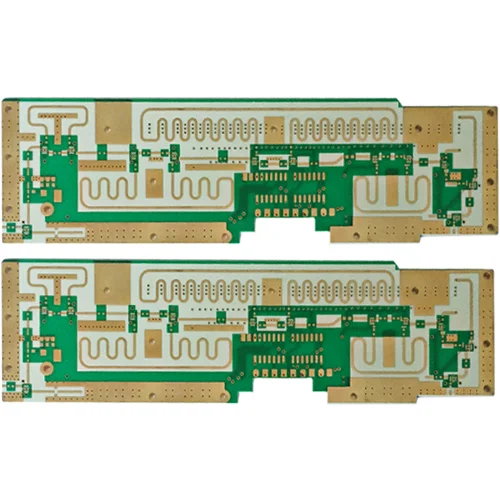

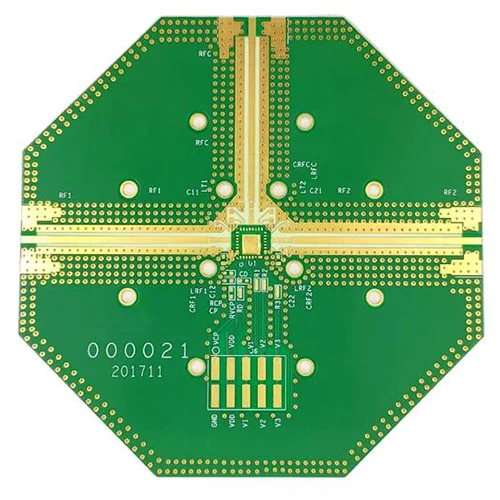

Where are high-frequency mixing boards used?

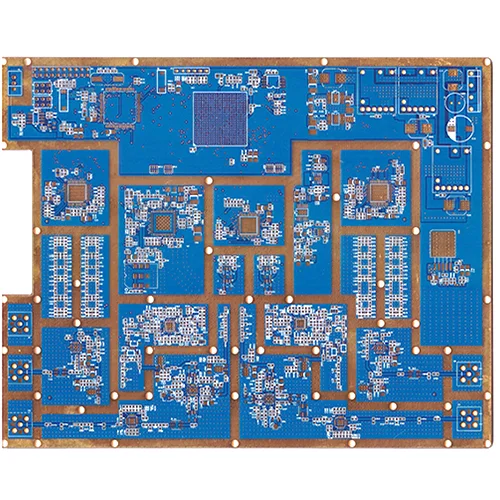

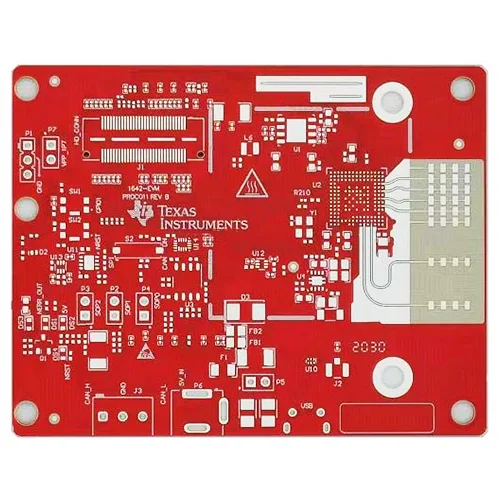

Satellite receivers, base station antennas, microwave transmission, car phones, global positioning systems, satellite communications, communication equipment connectors, receivers, signal oscillators, home appliance networks, high-speed computing computers, oscilloscopes, IC test instruments, etc., high-frequency communications. Intermediate frequency communications, high-speed transmission, high confidentiality, high transmission quality, high storage capacity processing and other communication and computer fields require high-frequency microwave printed circuit boards.

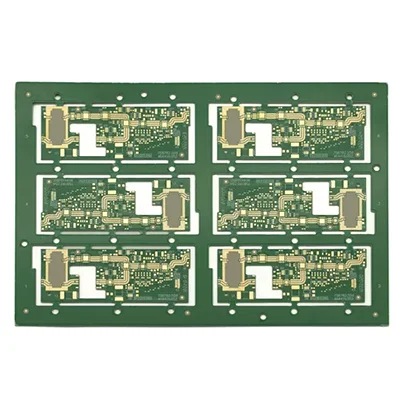

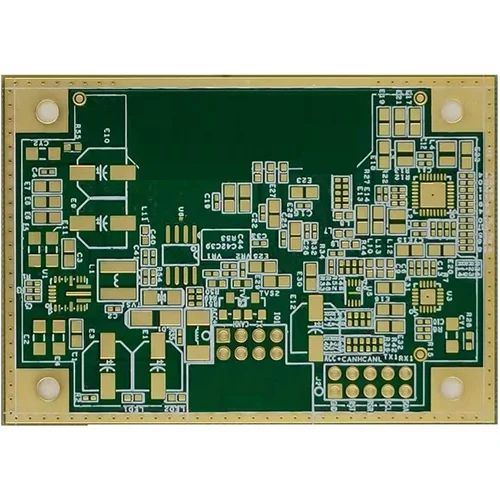

Microwave high-frequency hybrid PCB stacking method and characteristics

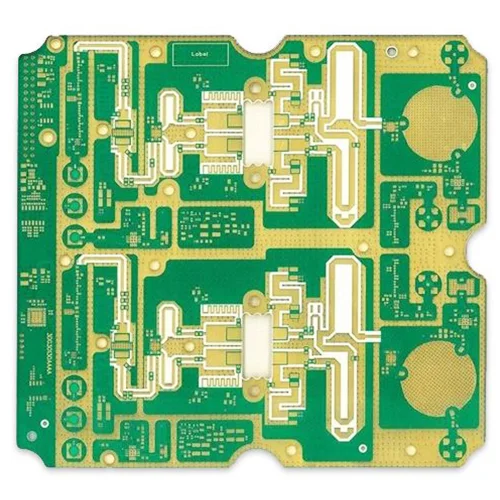

1. A high-frequency hybrid PCB controllable depth composite lamination structure, the high-frequency hybrid PCB includes L1 copper layer (high-frequency sheet), L2 copper layer (PP sheet), L3 copper layer (epoxy resin substrate), L4 copper layer in sequence; L2, L3, L4 copper layers are provided with slots of the same size at the same position; L4 copper layer is arranged with three-in-one buffer material from the inside to the outside, and steel plates and kraft paper are stacked from the outside to the outside; Aluminum plates, steel plates, and kraft paper are stacked on the L1 copper layer from the inside to the outside.

2. According to the first feature, the three-in-one buffer material is a buffer material sandwiched between two layers of release film.

3. According to the first feature, the laminated structure of the high-frequency board controlled depth mixed board of the present invention is characterized in that the high-frequency sheet is a polytetrafluoroethylene sheet.

The expansion and contraction characteristics of the high-frequency hybrid PCB composite board are different from those of the ordinary epoxy resin substrate, so the warping and shrinkage of the board are difficult to control, and the processing method of first grooving and then pressing will cause the board problem metal dents. The three-in-one buffer material is set on one side of the groove, and the buffer material can be filled into the groove hole during pressing to avoid the problem of dents. Kraft paper buffer pressure is set on both sides of the cardboard to balance the heat transfer uniformly, and the steel plate is set to ensure uniform heat conduction during pressing, so that the pressing is flat, and the heat and pressure during the pressing process are balanced, so as to better control the curvature and expansion of the board.

With the rapid development of 5G communication technology, higher frequency requirements are put forward for communication equipment. There are many microwave high-frequency hybrid PCBs on the market. The manufacturing technology of these microwave high-frequency hybrid PCBs also puts forward higher requirements. We have been specialized in IPCB processing for more than 10 years and can provide multi-layer hybrid PCB manufacturing services. We have all the equipment required for the entire process of multi-layer hybrid PCB production, comply with the ISO9001-2000 international standard management system, and have passed the iatf16949 and ISO 14001 system certification. Its products have passed UL certification and comply with IPC-A-600G and IPC-6012A standards. We can provide high-quality, high-stability, and high-adaptability microwave high-frequency hybrid PCB samples and batch services.

Data Sheet

| Product name: | High frequency hybrid PCB board |

| Board material: | Rogers Ro4350B+FR4 |

| Number of layers: | 12L |

| Board thickness: | 1. 6MM |

| Copper thickness: | finished copper thickness 1OZ |

| Impedance: | 50 ohms |

| Dielectric thickness: | 0. 508MM |

| Dielectric constant: | 3. 48 |

| Thermal conductivity: | 0. 69w/m. k |

| Flame retardant grade: | 94V-0 |

| Volume resistivity: | 1. 2*1010 |