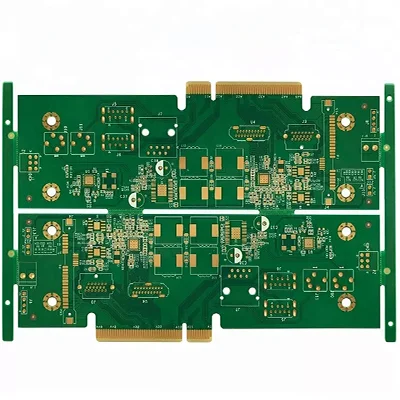

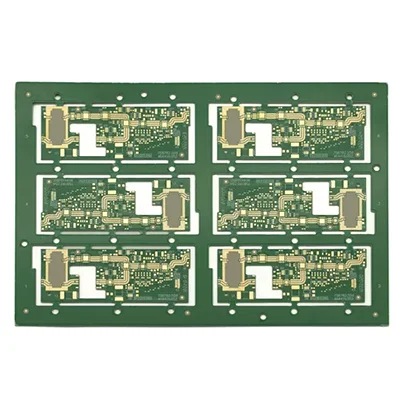

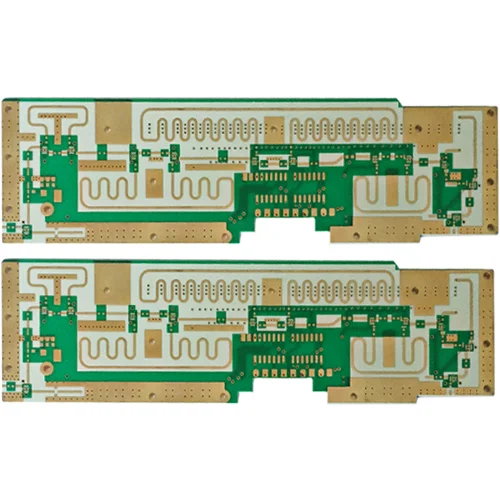

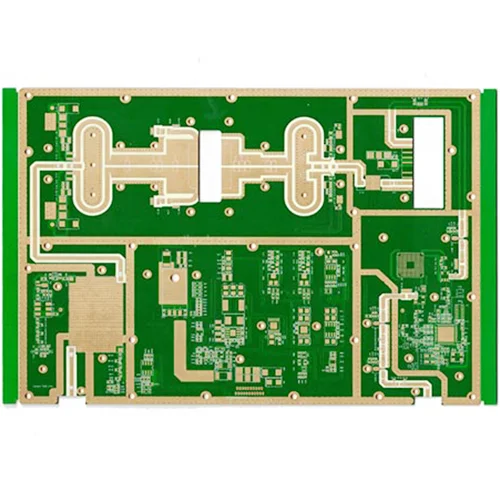

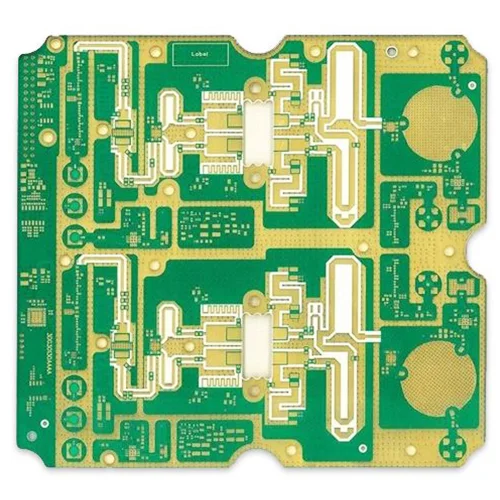

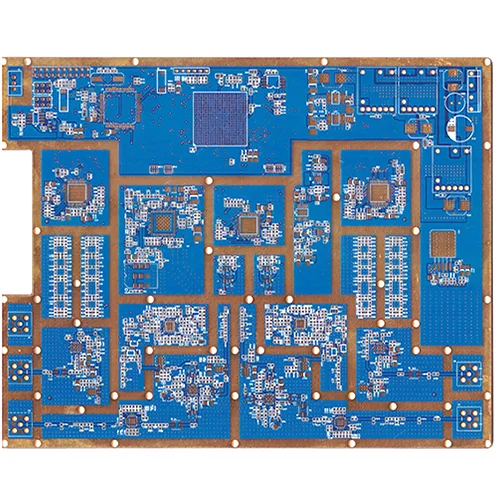

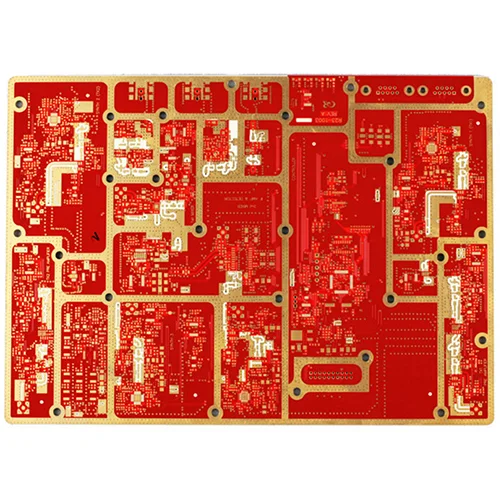

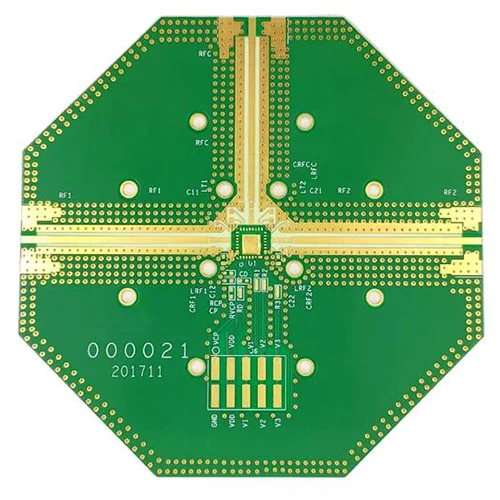

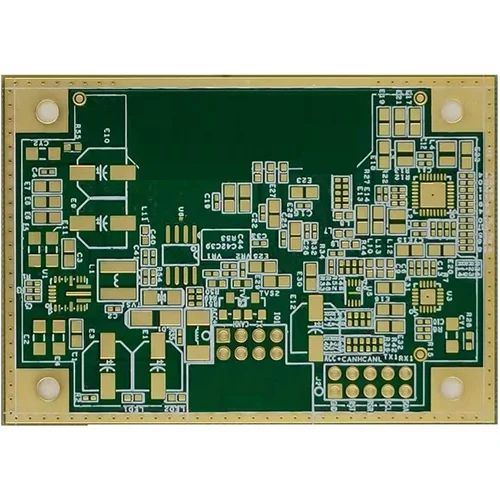

Millimeter Wave Radar PCB Circuit Board

Send Inquiry

Millimeter-wave radar mainly uses 24G radar PCB and 77G radar PCB. Millimeter-wave radar PCB is mainly used for automotive AI intelligent unmanned driving. Millimeter-wave radar PCB has broad application prospects. At present, the market prefers to use Rogers RO3003G2+ITEQ IT180 to mass-produce 77GHz millimeter-wave radar PCB

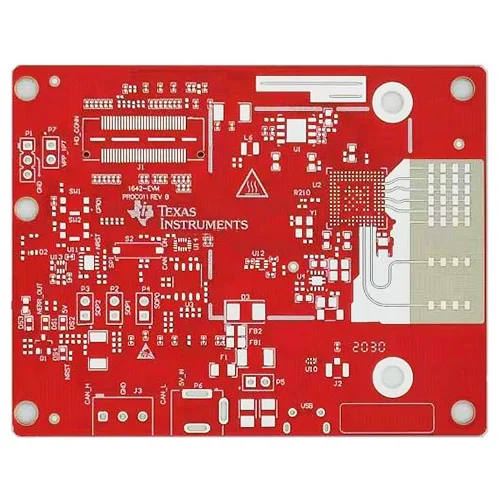

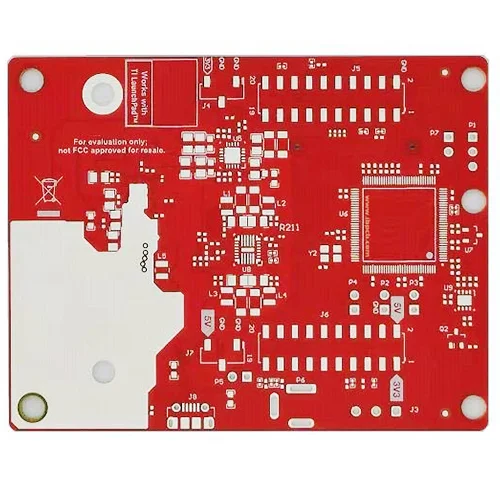

Differences in millimeter-wave radar sensors

A common feature of radar PCB design is the need for ultra-low loss radar PCB materials to reduce circuit losses and increase antenna radiation. Radar PCB materials are key components in radar sensor design. Choosing the right radar PCB material can ensure the stability and consistency of millimeter-wave radar sensors.

Millimeter-wave radar is the core technology for ADAS to improve safety and convenience. Target applications of mmWave radar:

Reversing Automatic Emergency Braking (R-AEB)

Front/Rear Cross Traffic Assist (FCTA/RCTA)

Parking Assist (PA)

Blind Spot Detection (BSD)

Cascaded Imaging Radar (IMR)

Automatic Emergency Braking (AEB)

Adaptive Cruise Control (ACC)

Lane Change Assist (LCA)

Radar 360° Perception

Data Sheet

| Name: | Millimeter wave radar PCB circuit board |

| Board: | Rogers RO3003+370HR |

| Dielectric constant: | High frequency material dielectric constant 3. 0 |

| Dielectric thickness: | 5mil (0. 127mm) |

| Number of layers: | 6L |

| Board thickness: | 1. 2mm |

| Copper thickness: | 1oz for inner and outer layers |

| Through hole: | Resin plug hole |

| Surface process: | Chemical silver deposition |

| Thermal conductivity: | 0. 69w/m. k |

| Loss: | 0. 001 |