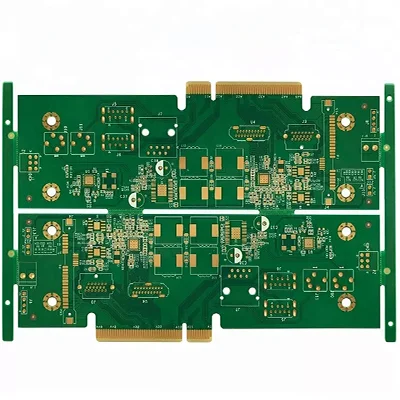

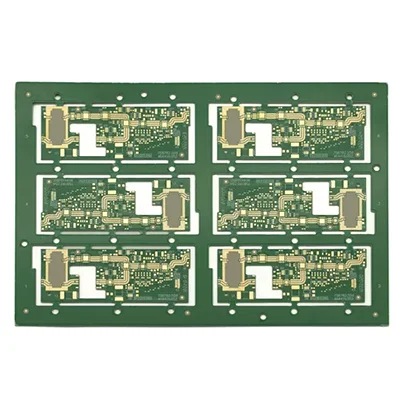

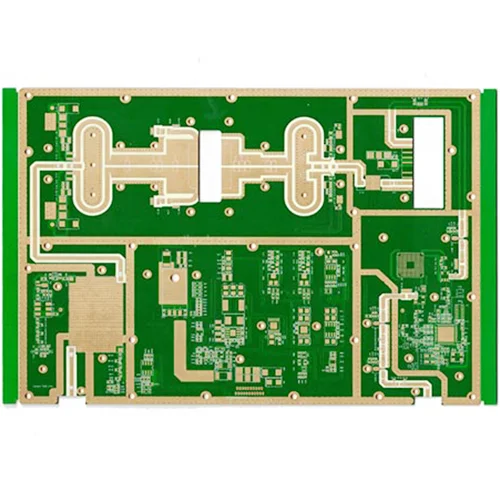

Fr4 Electronic Impedance Control PCB

Send Inquiry

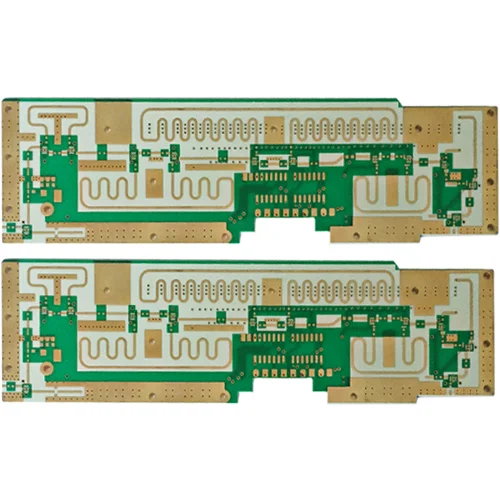

Five factors affecting impedance

First: dielectric thickness. Increasing dielectric thickness can increase impedance, while reducing dielectric thickness can reduce impedance; Different semi-solid tablets have different glue content and thickness. The pressed thickness is related to the flatness of the crusher and the program of the press plate; For any type of plate used, the thickness of the dielectric layer that can be produced must be calculated, which is conducive to design calculations. The trial mold tolerance is the key to dielectric thickness control.

Second: line width. Increasing line width can reduce impedance, while reducing line width can increase impedance. The control requirements of line width can better meet the gap of impedance control requirements within the tolerance of +/-10%. The gap cannot exceed 10%. The width is mainly controlled by etching control. To ensure the line width, the engineering film is compensated according to the etching side etching, photo-drawing error, and graphic transfer error to meet the line width requirements.

Third: copper thickness. Reducing line thickness can increase impedance, while increasing line thickness can reduce impedance; Line width can be controlled by graphic electroplating control or using copper foil of corresponding thickness. The control of copper thickness requires uniform control. The bleeding blocks of fine lines and isolation lines are added to prevent uneven copper thickness on the line, which affects the uneven impedance distribution to the copper distribution on the CS and SS surfaces. The board is passed on the board to achieve the purpose of double-sided copper thickness.

Fourth: Dielectric constant. Improving the dielectric constant can reduce impedance, and reducing the dielectric constant can increase impedance. The dielectric constant is mainly controlled by the material. Different boards have different dielectric constants. It is related to the resin material used: FR4 board, the dielectric constant is 3. 9-4. 5, which will increase with the increase of the frequency of use. 3. 9 A high impedance value is required to obtain high signal transmission, so that there can be a low dielectric constant.

Fifth: Welding thickness, printed welding will reduce external impedance. In general, printed welding can reduce single-ended 2 ohms and differential 8 ohms. 2 times the printing drop value is twice the time. When printed more than 3 times, the impedance value no longer changes.

Data Sheet

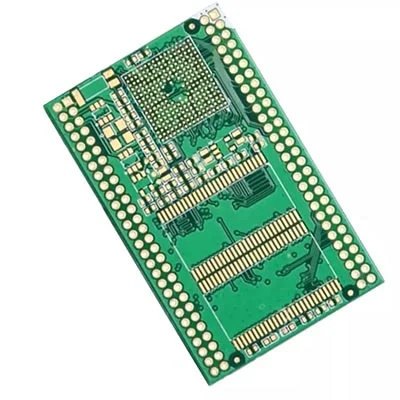

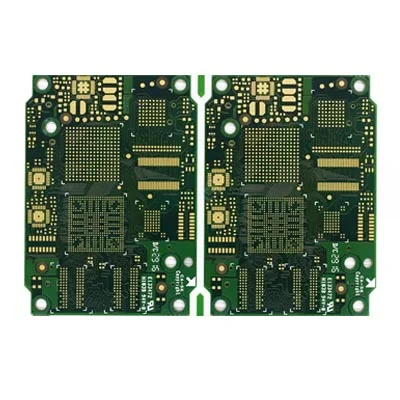

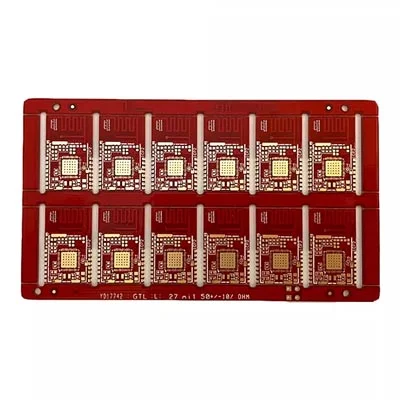

| Name: | Fr4 electronic impedance control PCB |

| Model: | printed circuit board |

| Base material: | FR-4 |

| Copper thickness: | 0. 5-40Z |

| Board thickness: | 0. 4T-4. 0T |

| Surface treatment: | HASL, OSP, immersion gold/gold plating |

| Board size: | 10*1200MM |

| Number of layers: | 1-20 layers |

| Solder mask: | green. Red. Blue. White. Black. Yellow |

| Size: | 10-1200MM |

| Circuit board inspection: | 100% electronic inspection |