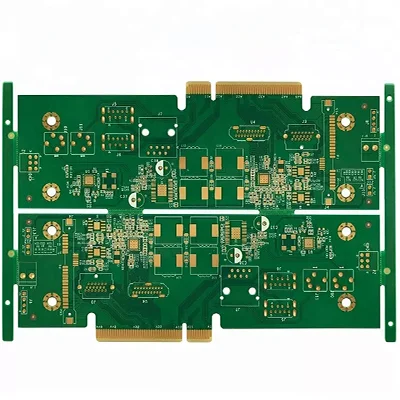

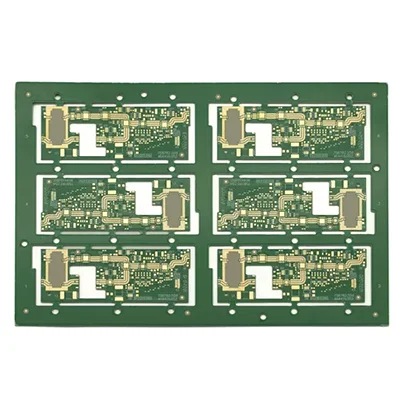

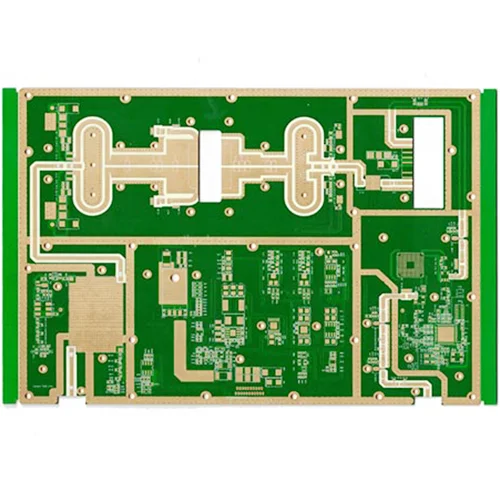

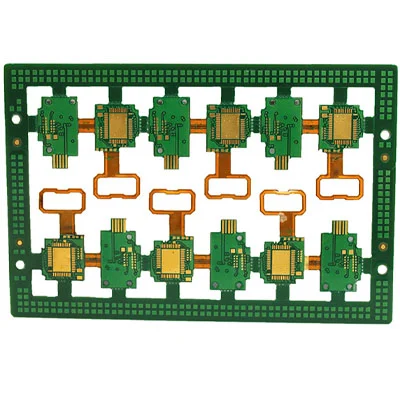

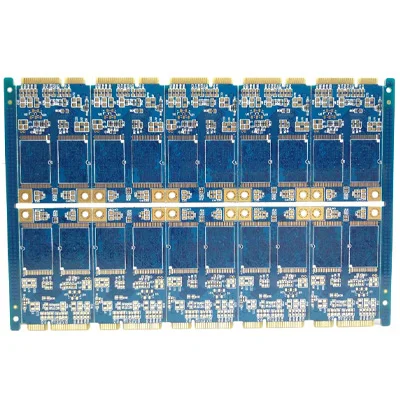

4-layer FR4 PCB

Send Inquiry

FR4 Materials and Properties

As the professional manufacturer, we would like to provide you 4-layer FR4 PCB. And we will offer you the best after-sale service and timely delivery. FR4 is a standard for glass fiber reinforced epoxy compounds defined by NEMA (National Electrical Manufacturers Association).

FR stands for "flame retardant" in English, indicating that the material meets the UL94V-0 flammability standard for plastic materials. The code 94V-0 can be found on all FR-4 PCBs. When the material catches fire, it is guaranteed that the fire will not spread and will be quickly extinguished.

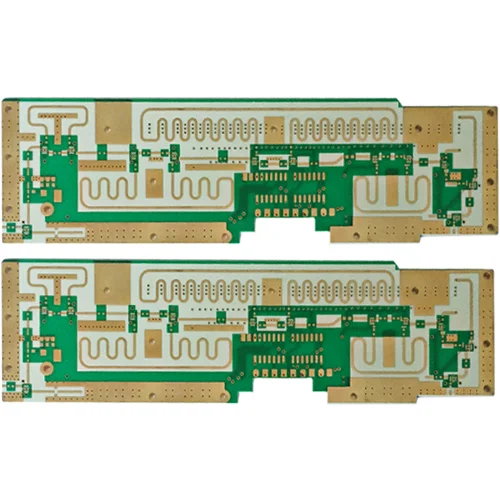

For high TG or HiTG, the glass transition temperature (TG) is 115°C to 200°C, depending on the manufacturing method and the resin used. A standard FR-4 PCB consists of one FR-4 layer sandwiched between two thin copper laminates.

FR-4 uses bromine, a fire-resistant chemical element called a halogen. It replaces G-10, another compound with lower resistance in most applications.

The advantage of FR4 is that it has a good strength-to-weight ratio. It does not absorb water, maintains high mechanical loads and provides good insulation in dry or humid environments.

Data Sheet

| Name: | 4-layer FR4PCB |

| Material: | FR4 |

| Board thickness: | 1. 6mm |

| Surface treatment: | HASL lead-free |

| Copper thickness: | 1OZ |

| Minimum line: | 6 million |

| Minimum hole: | 0. 3MM |

| Application: | Router |