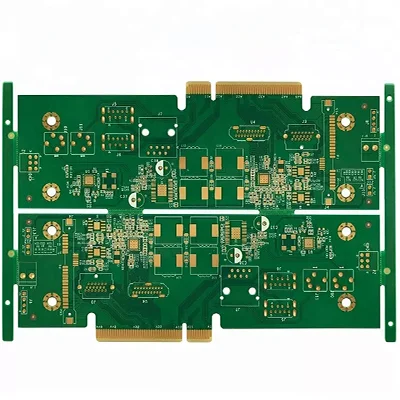

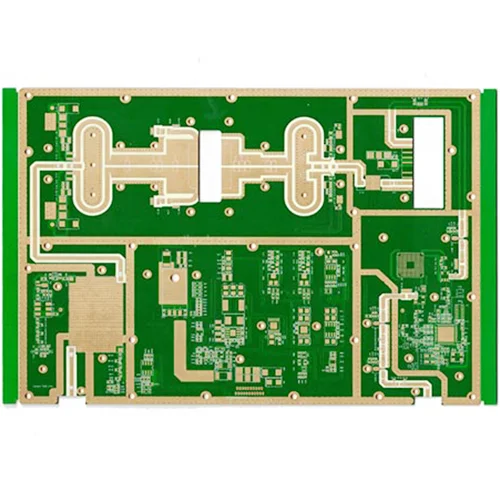

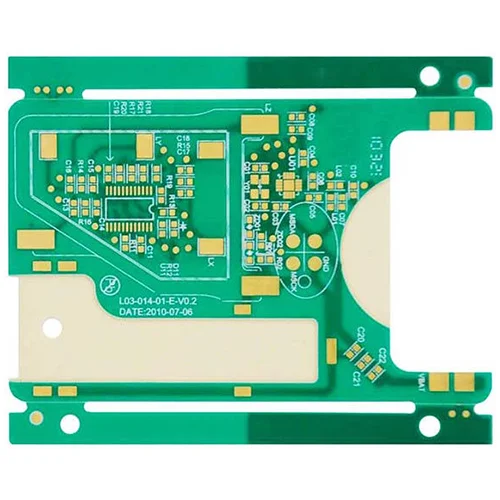

Taconic RF-35 High Frequency Board

Send Inquiry

Materials

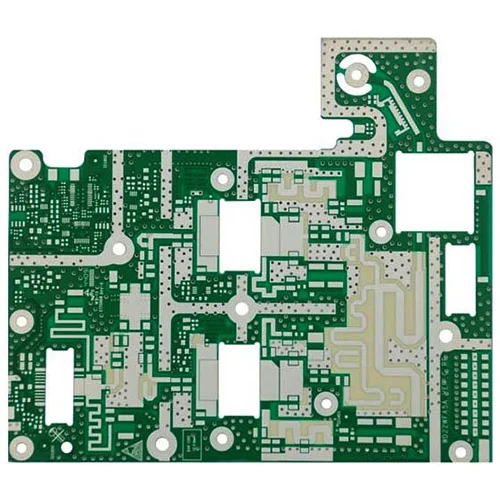

High-frequency circuit boards are an important part of many high-frequency systems. Unfortunately, over-amplification can damage high-frequency circuit boards. This happens when you overload high-frequency components. This can cause physical damage and breakage.

There are cases where high-frequency circuit boards fail. This can damage other components on the same PCB. To avoid this, high-frequency circuit boards should be made of high-quality materials. For example, ceramics and metals. Metals are a good choice because they can withstand high temperatures. For example, if power supplies get too hot, they can cause heat to build up. You should use ceramics. It absorbs vibrations and stress caused by components on other PCBs.

Advantages of Using Taconic RF-35 PCBs

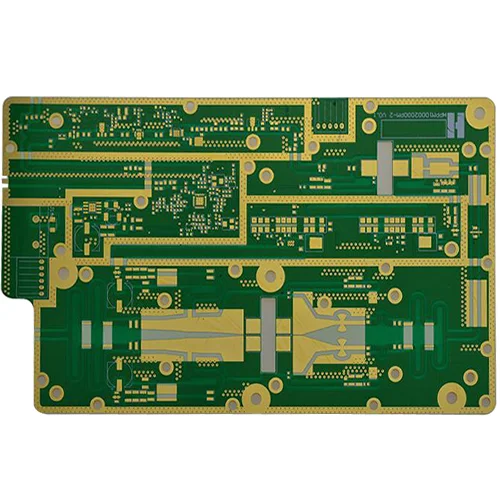

TaconIC RF-35 PCB designs improve the reliability of high-frequency systems. They provide the necessary components to reduce power consumption. They also improve heat resistance and stability. In addition, they extend the life of sensitive electronic devices.

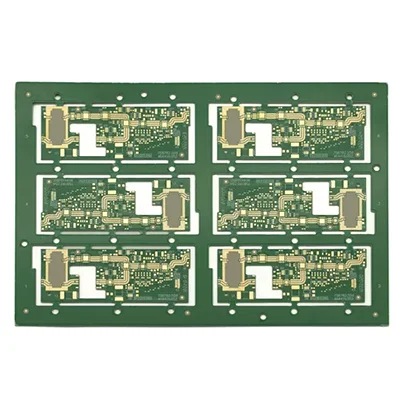

Manufacturers use a variety of high-quality materials to produce Taconic RF-35 PCBs. They also use innovative CAD processes. Therefore, they provide a high level of precision, efficiency, and functionality. These features allow PCB manufacturers such as RayMing PCB and Assembly to offer their customers a wide range of options. In the process, they maintain consistent product quality.

1. Low Cost

Taconic RF-35 PCBs are relatively cheap compared to other high-frequency components. This is because they are made of inexpensive materials such as paper, plastic, and fiberglass. This makes them ideal for mass production.

2. Lightweight

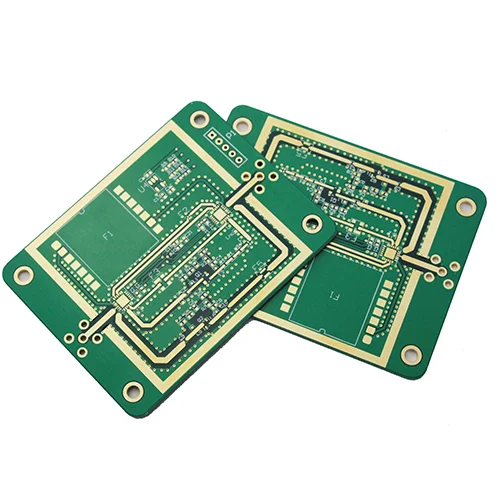

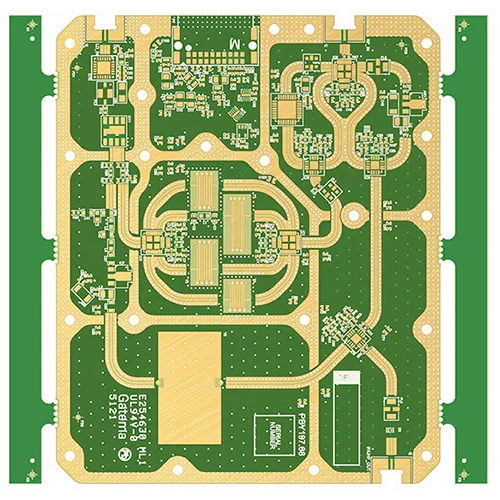

We can use lightweight materials to make Taconic RF-35 PCBs lightweight. They include paper, plastic, and fiberglass. It creates circuit boards and multi-layer designs. Multi-layer designs can also reduce the amount of material used to create PCBs. This feature is very convenient for producing lightweight but strong PCBs for ultralight aircraft. It is also suitable for aircraft that require high control accuracy and stability.

3. Excellent Peel Strength

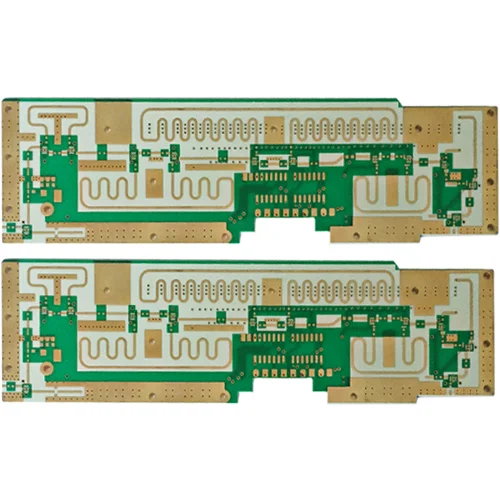

Manufacturers use a variety of materials to produce Taconic RF-35 PCBs. They also use processes that ensure their excellent peel strength. We can cut them using standard cutting saws, drilling equipment, or laser equipment. Taconic RF-35 PCBs can withstand high temperatures and have low thermal conductivity. This helps prevent overheating. High-frequency systems will not work properly without the right electrical components. Therefore, they become unstable and untrustworthy.

4. Tg above 600°F (315°C)

Taconic RF-35 PCBs can withstand high temperatures for more than an hour without loosening. This is because we laminate their material layers together through a multi-layer design. Then a layer of insulation separates this laminate. It helps to make Taconic RF-35 PCBs with a Tg of over 600°F (315°C).

5. Ultra-low moisture absorption

Taconic RF-35 PCBs have an ultra-low moisture absorption rate of less than 0. 5% of the dry material weight. This means that they do not absorb moisture as easily as other PCBs. Therefore, it has excellent corrosion, oxidation, and antibacterial capabilities.

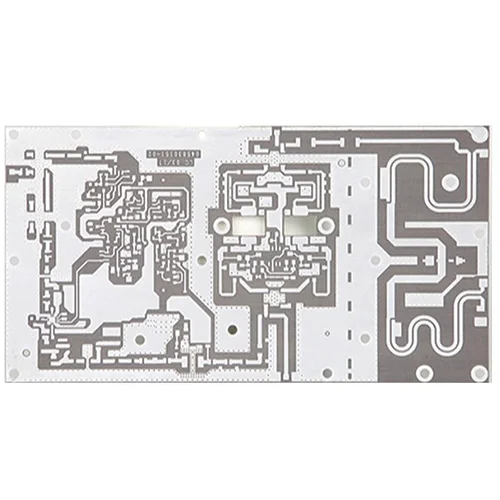

6. Enhanced Surface Finish

Taconic RF-35 PCBs feature enhanced surface smoothness. We can see this feature in the quality and uniformity of its surface. We can also see the impact of this quality on its functionality. For example, a smoother surface can improve the soldering process. It can also reduce the likelihood of defects such as dewetting, micro cracks, or skipping. In addition, a smooth surface can provide better performance due to increased contact between components.

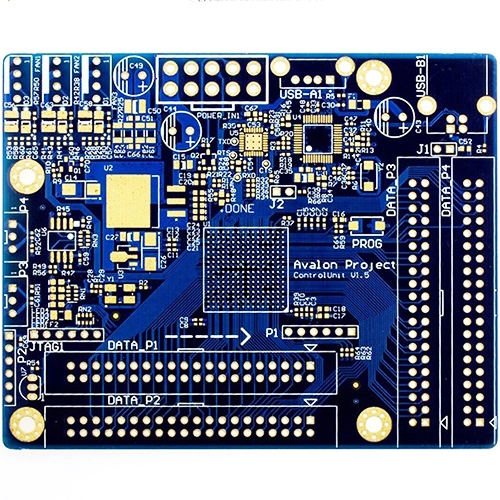

Data Sheet

| Name: | TaconIC RF-35 high frequency board |

| Board: | Taconic RF-35 |

| Number of layers: | 2L |

| Board thickness: | 0. 8mm |

| Copper thickness: | 1om |

| Surface treatment: | blue oil |

| Application: | communication |