Products

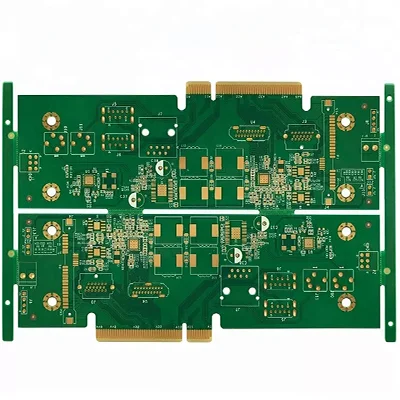

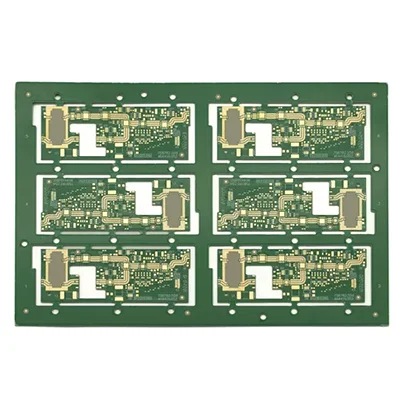

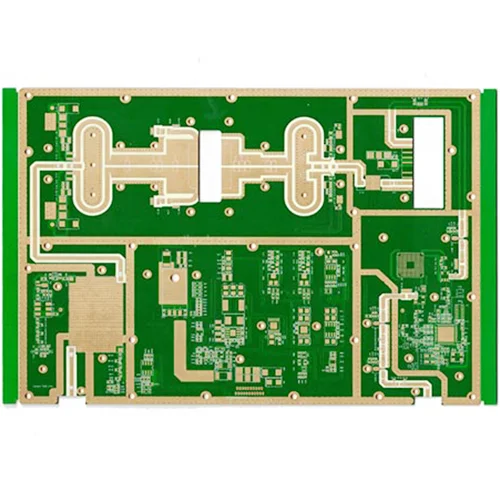

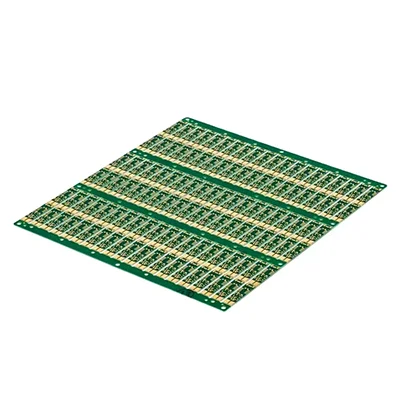

Multi-layer Gold Finger Motherboard Control PCB

For you, we can offer better pricing and competent service. Should you be intrigued by Multi-layer Gold Finger Motherboard Control PCB, kindly get in touch with us. We adhere to the standard of conscience-driven, committed service at the cost of quality assurance.OneWe adhere to the standard of conscience-priced, devoted service, so you can feel secure.

Send Inquiry

Product Description

Detailed processing of PCB gold fingers:

1. For PCB boards that need to be frequently plugged and unplugged, the gold fingers generally need to be hard-plated to increase the wear resistance of the gold fingers.

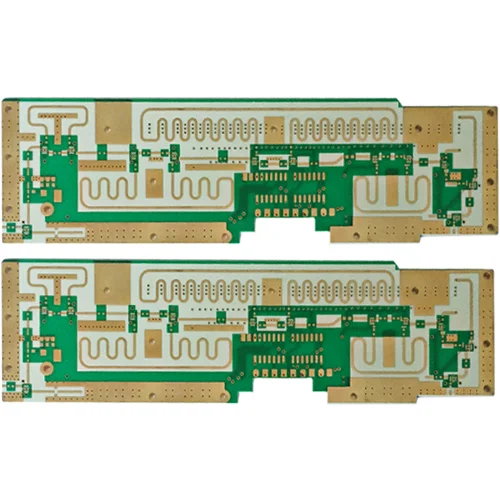

2. The gold fingers need to be tilted backwards, generally 45°, other angles such as 20°, 30°, etc. If the design does not tilt backwards, there is a problem. The arrow in the figure below shows a 45° tilt angle:

3. The gold finger needs to make a whole welding window. The PIN does not need to open the steel mesh;

4. The minimum distance between Shenxi and Shenyin pads is 14 million. It is recommended that the pad be more than 1mm away from the finger position, including the via pad;

5. Do not apply copper on the surface of the gold finger.

Data Sheet

| Name: | Multi-layer gold finger motherboard control PCB |

| Type: | Multi-layer circuit board |

| Number of layers: | 6 layers |

| Base material: | FR4, aluminum, high Tg FR4 |

| Copper thickness: | 0. 5-1 ounce |

| Board thickness: | 0. 4-4. 0mm |

| Aperture: | 0. 15-0. 2mm |

| Line width: | 0. 1-0. 3mm |

| Line spacing: | 0. 1-0. 3mm |

| Surface treatment: | immersion gold, tin spraying, gold finger |

| Solder mask: | green |

Hot Tags: Multi-layer Gold Finger Motherboard Control PCB

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy