What Makes FR4 PCB the Backbone of Modern Electronics ?

2025-10-31

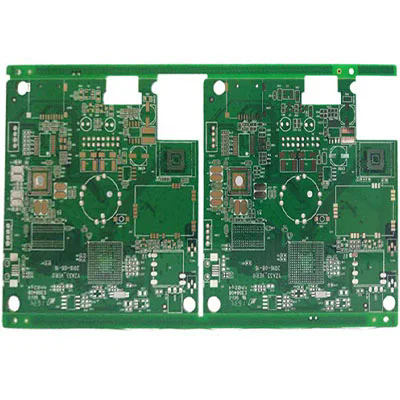

In the fast-evolving electronics industry, FR4 PCB (Flame Retardant Grade 4 Printed Circuit Board) stands as the most widely used and reliable base material for printed circuit boards. Known for its excellent mechanical strength, electrical insulation, and moisture resistance, FR4 PCBs have become the preferred choice for industries ranging from telecommunications and automotive to medical devices and consumer electronics.

The term FR4 refers to the glass-reinforced epoxy laminate sheet used as the substrate in PCB manufacturing. It ensures structural stability, maintains insulation between conductive layers, and supports high-density electronic circuits without degradation. The combination of fiberglass cloth and epoxy resin binder provides rigidity while keeping the board lightweight and heat-resistant.

What Makes FR4 PCB a Preferred Material?

FR4 material plays a critical role in balancing performance, cost-efficiency, and manufacturability. Its versatility allows it to be used in single-layer, double-layer, and multilayer PCB designs.

Key Advantages of FR4 PCB:

-

High Dielectric Strength:

FR4 maintains stable insulation resistance under high voltage, preventing electrical leakage. -

Excellent Thermal Stability:

With a glass transition temperature (Tg) typically between 130°C and 180°C, FR4 PCBs can operate in high-temperature environments. -

Mechanical Durability:

The fiberglass base provides rigidity and mechanical strength, minimizing deformation during assembly or operation. -

Cost-Effectiveness:

Compared to specialized materials like polyimide or ceramic, FR4 offers a perfect balance between performance and affordability. -

Moisture Resistance:

The epoxy resin matrix prevents water absorption, making FR4 suitable for humid environments. -

Chemical Resistance:

FR4 maintains structural and electrical integrity even when exposed to fluxes, cleaning agents, or environmental contaminants.

Typical FR4 PCB Technical Parameters

| Parameter | Standard FR4 PCB Value | Description |

|---|---|---|

| Glass Transition Temperature (Tg) | 130°C – 180°C | Temperature at which resin transitions from rigid to flexible |

| Dielectric Constant (Dk) | 4.2 – 4.8 @ 1 MHz | Determines signal transmission stability |

| Dissipation Factor (Df) | 0.015 – 0.02 @ 1 MHz | Represents energy loss in the dielectric |

| Volume Resistivity | ≥10^8 MΩ·cm | Indicates insulation resistance |

| Flexural Strength | ≥415 MPa (lengthwise) | Resistance to bending and mechanical stress |

| Water Absorption | ≤0.15% | Low moisture absorption rate |

| Flame Retardancy | UL94 V-0 | Self-extinguishing within 10 seconds |

Why FR4 PCB Is the Foundation of Modern Electronics

As electronic devices become smaller, faster, and more efficient, the demand for high-performance PCB materials has intensified. FR4 has remained the standard due to its adaptability and compatibility with advanced fabrication processes such as Surface Mount Technology (SMT), via drilling, and multilayer stacking.

Applications Across Industries:

-

Consumer Electronics: Smartphones, laptops, and wearable devices rely on FR4 PCBs for compact, lightweight circuitry.

-

Automotive: Engine control modules, LED lighting systems, and infotainment units use high-Tg FR4 to withstand temperature fluctuations.

-

Telecommunications: FR4 substrates are found in routers, base stations, and signal amplifiers requiring consistent signal transmission.

-

Medical Devices: Equipment such as ECG monitors and infusion pumps depend on FR4 for reliability and insulation.

-

Industrial Automation: Controllers, relays, and robotics use FR4 boards for stability in high-vibration environments.

Why Engineers Prefer FR4:

-

Balance of Strength and Flexibility: Supports both rigid and flex-rigid PCB configurations.

-

Compatibility with Lead-Free Soldering: Ideal for RoHS-compliant production.

-

Excellent Signal Integrity: Maintains consistent impedance for high-speed data transmission.

-

Customizable Thickness and Layer Count: Available from 0.2mm to 3.2mm and can accommodate 2 to 16+ layers.

Emerging Technological Trends:

The evolution of high-speed and high-frequency circuits is pushing FR4 to new limits. Manufacturers are now developing modified FR4 materials with lower dielectric constants (Dk < 4.0) and improved thermal dissipation. This advancement makes FR4 suitable for 5G communications, IoT modules, and automotive radar systems.

How FR4 PCB Supports Future Electronics Innovation

As the electronics industry transitions to smarter, smaller, and more sustainable designs, the next generation of FR4 PCBs must meet new challenges — thermal management, signal integrity, and environmental compliance.

High-Tg FR4: For Demanding Environments

High-Tg FR4 materials (Tg ≥ 170°C) have become essential in applications that experience continuous heat, such as power amplifiers, LED lighting, and electric vehicle systems. The higher glass transition temperature ensures that the PCB maintains structural stability even under sustained thermal load.

Low-Loss FR4: For High-Frequency Circuits

Low-loss FR4 materials are engineered for RF and microwave applications. They reduce signal attenuation and maintain impedance control, making them ideal for 5G antennas, satellite communication, and data centers.

Eco-Friendly FR4: Toward Sustainable Electronics

With increasing emphasis on environmental responsibility, halogen-free FR4 materials are gaining traction. These materials eliminate brominated flame retardants without compromising fire safety or mechanical strength. Manufacturers are also adopting recyclable fiberglass composites to reduce waste.

Smart Manufacturing Integration

Modern FR4 PCB production incorporates automated optical inspection (AOI), laser drilling, and CNC routing, ensuring precision and consistency. Combined with AI-driven design optimization and IoT-based quality monitoring, the FR4 PCB manufacturing process is more intelligent and efficient than ever before.

Frequently Asked Questions About FR4 PCB

Q1: What’s the difference between standard FR4 and high-Tg FR4 materials?

A1: The main difference lies in the glass transition temperature (Tg). Standard FR4 typically has a Tg of around 130°C, making it suitable for most consumer electronics. High-Tg FR4 ranges from 170°C to 180°C and is designed for high-temperature environments like automotive electronics and LED modules. High-Tg FR4 also exhibits improved mechanical stability and reduced delamination risk during soldering.

Q2: Can FR4 PCB be used for high-frequency or high-speed circuits?

A2: While standard FR4 is suitable for general-purpose designs, it may not perform optimally in high-frequency applications above 1 GHz due to dielectric losses. However, low-loss FR4 variants with reduced Dk and Df values have been developed for such use cases. These upgraded materials allow designers to maintain signal integrity in high-speed communication systems without significantly increasing cost.

The Future Outlook of FR4 PCB Technology

The global FR4 PCB market continues to grow steadily, driven by increasing demand for connected devices, EV technology, and smart infrastructure. As multilayer and high-density interconnect (HDI) designs become standard, FR4 materials are evolving to offer enhanced heat dissipation, lower dielectric losses, and improved reliability.

In the near future, hybrid PCB constructions — combining FR4 with high-frequency laminates like PTFE or Rogers materials — will enable cost-effective solutions for mixed-signal and RF applications. These innovations ensure that FR4 remains relevant even as electronic systems reach unprecedented levels of complexity.

Why FR4 PCB Remains the Industry Standard

FR4 PCBs have earned their reputation through a combination of reliability, versatility, and affordability. From smartphones to satellites, FR4 continues to serve as the foundation for countless innovations. Its adaptability to emerging technologies — from high-speed circuits to eco-friendly production — guarantees that FR4 will remain the material of choice for years to come.

As a trusted manufacturer, Viafull delivers high-quality FR4 PCBs engineered to meet the diverse needs of global clients. Every board is manufactured with precision, using advanced materials and state-of-the-art fabrication processes to ensure performance and durability.

For engineers, designers, and procurement specialists seeking custom FR4 PCB solutions, our team offers technical expertise, fast turnaround, and comprehensive support from prototype to mass production.

Contact us today to discover how Viafull’s FR4 PCB solutions can power your next-generation innovations.