Why Should You Choose Mixed Pressure PCB for Your Next Project?

2025-09-30

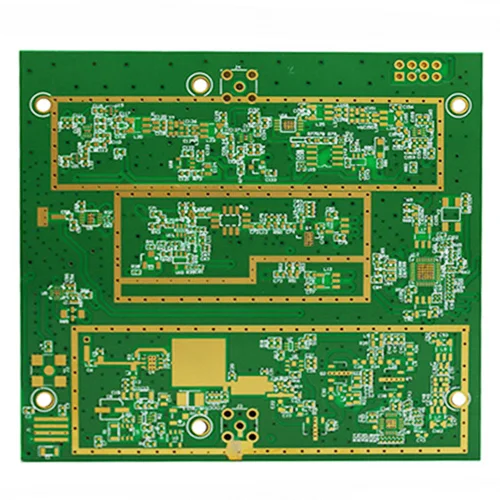

Printed circuit board (PCB) technology has evolved rapidly, responding to the growing demand for higher density, superior performance, and miniaturized designs in electronics. Among the many advanced PCB solutions, Mixed Pressure PCB stands out as a reliable and efficient option. This specialized board design integrates both high-pressure and low-pressure areas within a single PCB, offering manufacturers and engineers an innovative way to achieve precise functionality without compromising reliability.

In this article, we will explore the core features, technical parameters, benefits, and applications of Mixed Pressure PCB. We'll also provide professional insights into why industries increasingly rely on this technology, and answer common questions to help you better understand its advantages.

What Is Mixed Pressure PCB?

Mixed Pressure PCB refers to a type of printed circuit board that combines multiple pressure levels within a single structure. Unlike traditional PCBs that operate under uniform pressure or thermal conditions, these boards are engineered to handle different pressure requirements in different layers or sections. This makes them suitable for applications where varying mechanical, electrical, or thermal conditions exist in one device.

For example, high-pressure areas are designed for circuits requiring maximum durability and resistance, while low-pressure sections provide cost efficiency and flexibility. This unique design allows engineers to balance performance and budget in complex electronic products.

Why Is Mixed Pressure PCB Important in Modern Electronics?

The demand for compact and multifunctional electronic devices has pushed the limits of traditional PCB designs. A Mixed Pressure PCB provides the ideal solution by offering:

-

Enhanced durability in critical circuit zones exposed to high mechanical or thermal stress.

-

Cost-effective optimization by reducing unnecessary reinforcement in low-pressure regions.

-

Improved performance reliability across different components in the same device.

-

Flexibility in design for industries like telecommunications, aerospace, automotive, and medical electronics.

This balance of performance and efficiency makes Mixed Pressure PCB an essential choice in modern product engineering.

Key Features of Mixed Pressure PCB

-

Multi-pressure integration: Handles both high and low-pressure environments in a single board.

-

Superior bonding: Advanced lamination techniques ensure structural integrity.

-

Thermal stability: Excellent heat resistance for demanding environments.

-

High-density compatibility: Supports fine-pitch components and complex routing.

-

Customizable designs: Tailored to unique industry requirements.

Product Parameters of Mixed Pressure PCB

To illustrate the technical strength of our solution, here are the standard parameters of Mixed Pressure PCB manufactured by Guang dong Viafine PCB LIMITED:

| Parameter | Specification |

|---|---|

| PCB Type | Mixed Pressure PCB (multi-layer capability) |

| Layer Count | 4–32 layers |

| Material Options | FR4, High-Tg FR4, Polyimide, Rogers, Hybrid |

| Board Thickness | 0.2 mm – 6.0 mm |

| Copper Thickness | 1 oz – 6 oz |

| Minimum Line Width/Spacing | 3 mil / 3 mil |

| Surface Finish | HASL, ENIG, Immersion Tin, Immersion Silver |

| Thermal Resistance | 130°C – 260°C |

| Mechanical Strength | High tensile and compressive resistance |

| Applications | Aerospace, Automotive, Telecommunications, Medical Devices |

These parameters highlight how versatile and performance-driven the Mixed Pressure PCB can be, making it adaptable for both high-end and commercial electronics.

How Does Mixed Pressure PCB Perform in Real Applications?

The performance of Mixed Pressure PCB is evident in industries that demand precision and durability:

-

Aerospace and Defense: Withstands extreme environments while ensuring signal reliability.

-

Automotive Electronics: Provides thermal management and durability for critical systems like engine control units and infotainment devices.

-

Medical Devices: Supports miniaturization while maintaining safety and performance in diagnostic and monitoring equipment.

-

Telecommunications: Ensures stable high-frequency transmission in advanced communication devices.

By balancing strength and efficiency, Mixed Pressure PCB proves invaluable in applications requiring diverse operating conditions.

Benefits of Choosing Mixed Pressure PCB

-

Cost Efficiency – No need to over-engineer the entire board; reinforcement is used only where required.

-

Space Optimization – Allows compact design without sacrificing reliability.

-

High Performance – Supports demanding electrical and thermal requirements.

-

Custom Engineering – Tailored to meet industry-specific challenges.

-

Long-Term Reliability – Reduced risk of board failure in varying operating environments.

FAQ About Mixed Pressure PCB

Q1: What makes Mixed Pressure PCB different from traditional multilayer PCBs?

A1: Unlike standard multilayer PCBs that have uniform pressure resistance throughout, Mixed Pressure PCB combines both high and low-pressure sections in one design. This allows manufacturers to optimize cost and performance simultaneously, making it more efficient for complex applications.

Q2: Can Mixed Pressure PCB handle high-frequency applications?

A2: Yes. With advanced materials such as Rogers and Polyimide, Mixed Pressure PCB is fully capable of supporting high-frequency and high-speed signal transmission, which is crucial for telecommunications and aerospace industries.

Q3: What industries benefit most from Mixed Pressure PCB?

A3: Industries like aerospace, automotive, telecommunications, and medical electronics rely heavily on Mixed Pressure PCB because of its durability, design flexibility, and ability to perform under diverse conditions.

Q4: How does Guang dong Viafine PCB LIMITED ensure the quality of Mixed Pressure PCB?

A4: We employ advanced lamination, precision drilling, strict testing, and international quality control standards. Every Mixed Pressure PCB is inspected for thermal stability, mechanical strength, and electrical performance before shipment.

Why Partner with Guang dong Viafine PCB LIMITED?

At Guang dong Viafine PCB LIMITED, we specialize in producing advanced PCB solutions tailored to global market needs. With decades of expertise, state-of-the-art facilities, and a dedicated engineering team, we ensure that every Mixed Pressure PCB meets stringent industry standards.

Whether you need small-batch prototypes or large-scale production, our manufacturing capabilities and customer-focused services ensure consistent results.

Conclusion

Choosing the right PCB solution is crucial for the performance and reliability of your product. Mixed Pressure PCB offers an innovative balance between durability and cost-efficiency, making it the preferred choice across multiple industries.

If you are looking for a trusted partner to provide high-quality Mixed Pressure PCBs, Guang dong Viafine PCB LIMITED is here to deliver reliable solutions with unmatched precision.

Contact us today to discuss your requirements and discover how our expertise can bring your project to life.