Why Has Green Oil PCB Become An Important Part Of Electronic Manufacturing?

2025-06-16

As modern electronic products have increasingly higher requirements for reliability and precision, a high-quality PCB is no longer just a medium for "powering on", but the core of the entire circuit system. Among the many protection mechanisms of PCB, Green Oil PCB is gradually becoming an important part that cannot be ignored in the electronic manufacturing industry. It is not only a coating for surface protection, but also the key to stability, durability and performance assurance.

Why Does Green Oil PCB Make Circuit Boards More Durable?

The green ink of Green Oil PCB not only serves as a logo, but also has four core functions: preventing conductor lines from breaking due to physical damage, avoiding short circuits during welding, reducing copper contamination of solder baths, and resisting insulation degradation and corrosion caused by dust and moisture. It is precisely because of these protections that the circuit board can run in a highly stable state for a long time, which is particularly suitable for industrial equipment, communication terminals, medical instruments and other fields with extremely high quality requirements.

What Are The Structural Requirements Of Green Oil PCB?

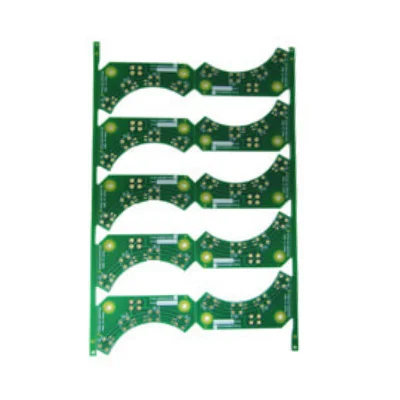

This Green Oil PCB adopts high-performance FR4 TG150 substrate, has good heat resistance and mechanical strength, and is suitable for a variety of high-temperature welding processes. The board layer is a commonly used double-sided structure, the finished board thickness is 1.6 mm, and the copper thickness is 1 ounce inside and outside, ensuring stable conductivity under the premise of limited space. The surface treatment adopts ENIG to enhance welding reliability and anti-oxidation ability, which is very suitable for high-density patch application scenarios.

What Problems Can Green Oil PCB Solve For Buyers?

Many electronic products perform well at the beginning of the factory, but after half a year or a year, they have problems such as poor contact or circuit aging. Green Oil PCB can significantly delay the occurrence of this "invisible aging" with its stable coating protection performance, especially in high humidity, high dust or easily oxidized environment. For overseas buyers, this not only means higher product stability, but also means less after-sales maintenance costs and longer market reputation cycle.

Why Choose Us?

Founded in 2009, Guang Dong Viafine PCB LIMITED is a professional printed circuit board (PCB) printed circuit board assembly (PCBA) integrated service high-tech enterprise, specializing in the R&D and production of high-precision multilayer boards and special boards.

From consumer electronics and industrial automation to smart homes and traffic control systems, more and more end products are considering Green Oil PCB as a standardized solution. Its green ink not only reflects environmental awareness, but also is an engineering guarantee — it gives the circuit board a longer service life, stronger environmental adaptability and better welding stability. In an era where large-scale manufacturing and high-end customization coexist, Green Oil PCB is not only a blessing for detail control but also a safe option for bulk purchases. Learn more about what we offer by visiting our website at https://www.viafinegroup.com/. For questions or support, contact us at sales13@viafinegroup.com.