Why Can't Industrial Automation Be Separated From Industrial Control PCBA?

2025-06-09

In modern industrial control systems, industrial control PCBA plays a core role. It is not only the brain of electronic equipment, but also the hub of data transmission and system operation. Unlike ordinary PCB, PCBA is a finished circuit board after a complete processing process, with all components welded and can be put into use directly. This process covers multiple steps such as patch, plug-in, welding and testing, ensuring the stability and reliability of the circuit, and is the preferred solution for high-demand industrial scenarios.

How Can Factories Improve Equipment Performance Through High-Standard PCBA?

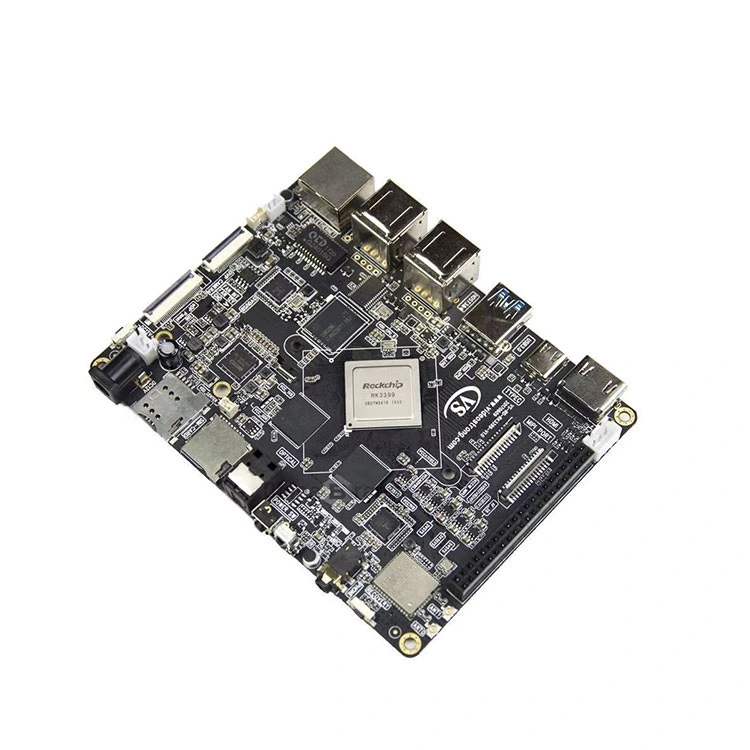

The performance of Industrial Control PCBA directly determines the response speed and operation stability of industrial equipment. This model PCBA adopts a high-reliability Rigid PCB structure with an 8-layer wiring design, supporting more complex circuit construction and higher computing density. The configuration of 1oz copper thickness can effectively reduce the risk of heat while ensuring conductivity; the 2mm board thickness provides stronger mechanical strength, especially suitable for high-vibration and high-impact industrial environments. Every detail is aimed at "high performance" to help customers build more efficient and durable control systems.

How Is The Accuracy Of Industrial Control PCBA Reflected In The Details?

Excellent PCBA is not only about reasonable circuit design, but also about its process accuracy. This industrial control PCBA has a minimum aperture of 0.2mm and a minimum line width/line spacing of 8mil, which ensures high-precision connection under dense wiring and avoids signal interference and current short circuit. In addition, the ENIG (chemical nickel-gold plating) surface treatment process makes the solder joints smoother and more resistant to oxidation, greatly improving the solderability and long-term reliability of the product. The optimization of these technical details provides a strong guarantee for the stable operation of the automation system

This product fully complies with the IPC-A-600 standard and represents the manufacturing benchmark for high-quality circuit boards. From design to delivery, the quality management system is strictly implemented in every link, equipped with a green solder mask and white logo to facilitate customer subsequent maintenance and debugging. Standardized appearance and logo also help to improve the overall process image of the terminal product and meet the strict requirements of overseas buyers for product compliance and traceability.

Why Choose Us?

Industrial control PCBA is widely used in automation equipment, robot systems, power control, instrumentation, traffic management systems and other fields. Its multi-layer design and high-reliability welding technology enable it to adapt to the high-frequency, long-term, and continuous operation requirements in complex industrial environments. Whether you are engaged in smart manufacturing, energy management, or industrial Internet of Things development, this PCBA can provide stable and efficient technical support for your project.

Founded in 2009, Guang Dong Viafine PCB LIMITED is a professional printed circuit board (PCB) printed circuit board assembly (PCBA) integrated service high-tech enterprise, specializing in the R&D and production of high-precision multilayer boards and special boards. Learn more about what we offer by visiting our website at https://www.viafinegroup.com/. For questions or support, contact us at sales13@viafinegroup.com.